A Cricket Bat Master's Story: Generations Of Craftsmanship

Table of Contents

The Legacy of a Cricket Bat Maker

Meet David Miller, a master cricket bat craftsman with over 40 years of experience. His family's history in cricket bat making stretches back over a century, a true family tradition of cricket bat making. David's early memories are filled with the scent of freshly cut willow and the rhythmic sounds of his father's tools. He began his apprenticeship at the age of 12, learning the intricacies of the craft from his father and grandfather, inheriting the mantle of master cricket bat craftsman. He's now passing on these invaluable skills to his own son, ensuring the cricket bat heritage continues. His dedication has earned him numerous awards and recognition for his exceptional cricket bat craftsmanship, solidifying his place as a leading figure in the industry.

- Family history in cricket bat making: Four generations of Millers have crafted cricket bats, each contributing to the refined techniques used today.

- Early memories and apprenticeship: David recalls spending countless hours in his father's workshop, absorbing the nuances of the craft.

- Passing on the skills to the next generation: David's son, Alex, is learning the trade, ensuring the family's legacy of cricket bat making continues for years to come.

- Awards and recognition received for craftsmanship: David's bats have been lauded for their exceptional quality and performance, earning him several prestigious awards within the cricket community.

The Art of Selecting the Perfect Willow

The journey to creating a premium willow cricket bat begins long before the first cut. Selecting the right willow is paramount; David primarily uses English Willow, renowned for its superior grain density and strength, although he also sources high-quality Kashmir Willow for specific customer requests.

- Characteristics of high-quality willow: David meticulously examines each piece of willow, looking for straight, close-grained wood with minimal knots. Grain density is crucial for the bat's strength and "sweet spot."

- Sourcing the willow: Sustainability is key. David sources his willow from reputable suppliers who employ sustainable forestry practices, ensuring a consistent supply of premium willow for cricket bats.

- Visual inspection process: Each piece of willow undergoes a rigorous visual inspection; the slightest imperfection can render it unsuitable.

- Rejection rate of unsuitable wood pieces: A significant percentage of willow is rejected, highlighting the high standards maintained throughout the process of selecting cricket bat willow. Only the finest pieces are deemed worthy of becoming a cricket bat.

The Meticulous Crafting Process

The crafting of a handcrafted cricket bat is a labor of love, a precise process that combines traditional techniques with modern tools. From cleaving the willow to the final sanding, every step requires skill and precision.

- Cleaving: The initial process of splitting the willow log into suitable pieces for the bat's construction.

- Shaping: The pieces are carefully shaped using specialized tools, ensuring the bat's profile meets the required specifications.

- Pressing: The shaped pieces are pressed together to create the bat's face, a process requiring significant pressure and expertise.

- Hand-finishing techniques: This is crucial for achieving the perfect balance and feel of the bat. It involves smoothing, shaping, and adding the finishing touches to the bat's handle and blade.

- Quality control checks: At each stage, David meticulously checks the bat's quality, ensuring that only perfect cricket bats leave his workshop. The importance of hand-finishing techniques cannot be overstated. They are what separates a high-quality bat from an average one.

The Significance of the "Sweet Spot"

The "sweet spot" is the area on the bat's face that provides optimal power and control when hitting the ball. Achieving the perfect cricket bat sweet spot is a hallmark of David's craftsmanship.

- Achieving the perfect sweet spot: Years of experience and meticulous attention to detail allow David to consistently achieve the optimal sweet spot. This involves precise shaping and balancing of the bat.

- Impact on batting power and control: A well-defined sweet spot maximizes the power transfer from the bat to the ball, offering enhanced control and reduced vibrations.

- Testing and adjustments: Each bat undergoes rigorous testing to ensure its sweet spot is perfectly positioned and performs optimally. Adjustments are made to fine-tune the balance and feel of each cricket bat.

Preserving the Tradition for Future Generations

Passing down the craft of cricket bat making presents unique challenges and immense rewards. David's dedication to preserving cricket bat craftsmanship is evident in his mentorship of his son and his embrace of new technologies while still holding fast to traditional methods.

- Apprenticeships and mentorship: David believes in the importance of a formal apprenticeship, passing his knowledge and skills to the next generation of cricket bat makers.

- Impact of modern technology: While traditional methods are preserved, modern tools aid in efficiency without compromising quality. The blend of old and new techniques is key to the future of cricket bat making.

- The future of traditional cricket bat craftsmanship: David is optimistic about the future, believing that the demand for handcrafted cricket bats will continue to grow, driven by the appreciation for quality, heritage, and skill.

Conclusion

The story of David Miller is a testament to the dedication, skill, and rich history behind each handcrafted cricket bat. The meticulous process, from selecting the finest willow to achieving the perfect sweet spot, showcases the artistry and passion inherent in this time-honored craft. Preserving this tradition ensures that future generations can experience the unparalleled quality and performance of a truly handcrafted cricket bat. Experience the difference of a truly handcrafted cricket bat. Explore our collection of expertly crafted bats, made with generations of experience and passion. Discover the legacy of cricket bat craftsmanship today! [Link to website]

Featured Posts

-

Fashion Heritage Ballet And Puns Your Weekend Events Guide

May 23, 2025

Fashion Heritage Ballet And Puns Your Weekend Events Guide

May 23, 2025 -

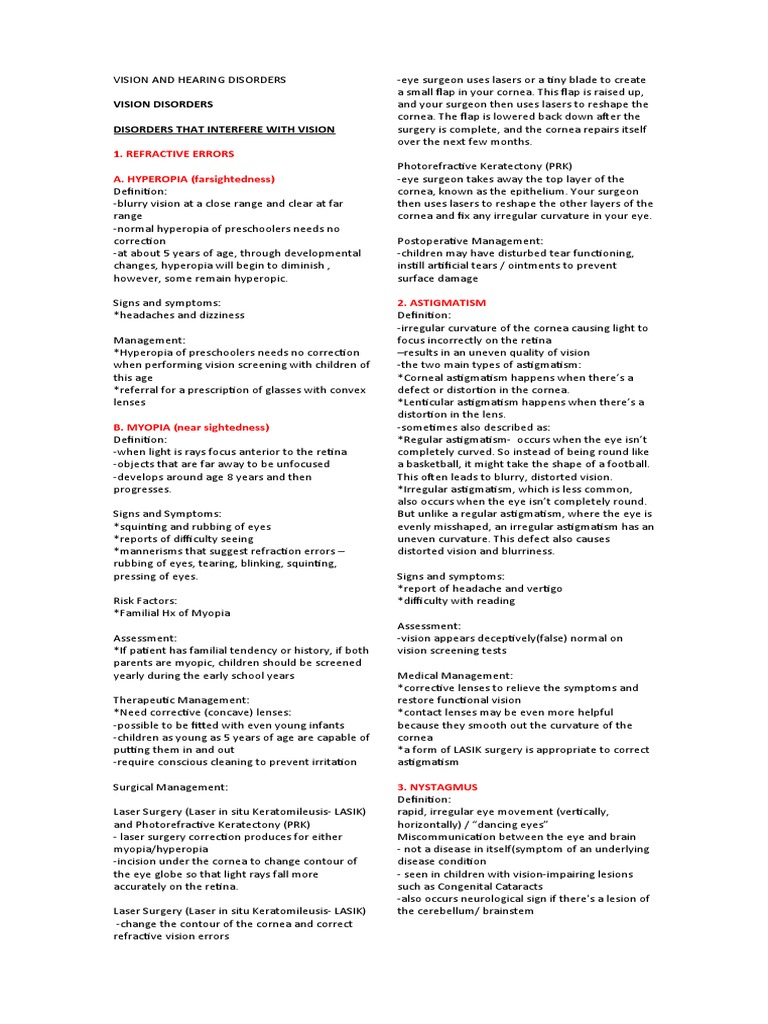

Roger Daltrey 81 And The Challenges Of Hearing And Vision Loss

May 23, 2025

Roger Daltrey 81 And The Challenges Of Hearing And Vision Loss

May 23, 2025 -

Market Instability Us Fiscal Issues Weigh On Stock Prices

May 23, 2025

Market Instability Us Fiscal Issues Weigh On Stock Prices

May 23, 2025 -

Msharkt Ebd Alqadr Fy Hzymt Qtr Amam Alkhwr Baldwry

May 23, 2025

Msharkt Ebd Alqadr Fy Hzymt Qtr Amam Alkhwr Baldwry

May 23, 2025 -

September Show Marks Grand Ole Oprys Centennial In London

May 23, 2025

September Show Marks Grand Ole Oprys Centennial In London

May 23, 2025

Latest Posts

-

Assessing The Success Of Manchester Uniteds Noussair Mazraoui Signing

May 23, 2025

Assessing The Success Of Manchester Uniteds Noussair Mazraoui Signing

May 23, 2025 -

Did Manchester United Make The Right Choice Signing Noussair Mazraoui

May 23, 2025

Did Manchester United Make The Right Choice Signing Noussair Mazraoui

May 23, 2025 -

Noussair Mazraoui A Game Changer For Manchester United

May 23, 2025

Noussair Mazraoui A Game Changer For Manchester United

May 23, 2025 -

The Mazraoui Transfer A Success For Manchester United

May 23, 2025

The Mazraoui Transfer A Success For Manchester United

May 23, 2025 -

Costly Mistakes Jaap Stam Assesses Man United Under Ten Hag

May 23, 2025

Costly Mistakes Jaap Stam Assesses Man United Under Ten Hag

May 23, 2025