Assessing The Feasibility Of Returning Factory Jobs To The US Under Trump's Policies

Table of Contents

Trade Policies and Their Impact on Reshoring

Trump's administration implemented significant changes to US trade policy, aiming to boost domestic manufacturing and reshore jobs. However, the effectiveness of these measures remains a subject of ongoing debate.

Tariffs and Their Effectiveness

The imposition of tariffs on imported goods was a key element of Trump's trade strategy. The intended effect was to make imported goods more expensive, thereby increasing the competitiveness of domestically produced goods and stimulating US manufacturing.

- Impact on Consumer Prices: Tariffs, while potentially benefiting some domestic industries, often lead to higher prices for consumers. This can reduce consumer purchasing power and negatively impact overall economic growth.

- Retaliatory Tariffs: The imposition of tariffs often provokes retaliatory measures from other countries, leading to trade wars that can harm both exporting and importing nations. The US experienced this with China, resulting in disruptions to supply chains and increased uncertainty for businesses.

- Industry-Specific Effects: Some industries, such as steel, saw temporary benefits from tariffs, experiencing increased domestic production. However, other industries, particularly those reliant on imported components, faced significant challenges due to increased input costs. The textile industry, for example, faced both benefits and challenges depending on the specific inputs and products.

Pros and Cons of Tariff-Based Reshoring:

- Pros: Potential for increased domestic production in targeted industries, protection of certain jobs.

- Cons: Higher prices for consumers, potential for trade wars, risk of harming industries reliant on imports.

Trade Deals and Negotiation Strategies

The Trump administration renegotiated existing trade deals, such as NAFTA (renamed USMCA), and pursued new bilateral agreements. The stated aim was to create more favorable terms for US manufacturers and workers.

- USMCA and its Impact: The USMCA, while aiming to improve conditions for US manufacturers, did not dramatically alter the overall landscape of North American manufacturing. The impact on reshoring was limited, and the deal's ultimate effects are still being assessed.

- Success and Failures of Negotiation Tactics: While some trade deals were renegotiated, Trump's aggressive tactics also led to increased trade tensions and uncertainty for businesses. This uncertainty hindered investment and job creation, undermining the intended benefits.

- Long-Term Effects of Altered Trade Relationships: Changes to established trade relationships can have long-term consequences, impacting supply chains, investment decisions, and the overall competitiveness of US industries. The long-term effects of Trump's trade policies on US manufacturing are still unfolding.

Factors Beyond Trade: Automation and Labor Costs

While trade policy plays a role, other crucial factors influence the feasibility of reshoring factory jobs to the US.

The Role of Automation in Manufacturing

Automation is transforming the manufacturing landscape, reducing the need for manual labor. This technological shift significantly impacts job creation and displacement.

- Automation and Job Displacement: Increased automation leads to fewer jobs in traditional manufacturing roles, counteracting efforts to reshore jobs.

- Industries Affected by Automation: The automotive, electronics, and food processing industries are prime examples where automation has significantly reduced the need for manual labor.

- Impact on Reshoring Efforts: The widespread adoption of automation makes it challenging to reshore jobs in industries where labor costs are a significant factor, even with favorable trade policies. Reshoring becomes more about attracting high-skilled workers for automation-related roles.

Labor Costs and Competitiveness

The relatively high labor costs in the US compared to other manufacturing hubs pose a significant challenge to reshoring efforts.

- US Labor Costs vs. Global Competitors: The cost of labor in the US is substantially higher than in many countries in Asia and Latin America, making it difficult to compete on price.

- Challenges of Competing with Lower Labor Costs: This price difference creates a significant hurdle for US manufacturers attempting to compete with companies based in countries with significantly lower labor costs.

- Increasing US Labor Productivity: To offset higher wages, the US must focus on boosting labor productivity through technological advancements, training, and improved efficiency.

- Challenges in Cost Competitiveness: Unless substantial improvements are made in productivity and automation efficiencies, the US will likely struggle to compete on price with low-labor-cost countries.

Infrastructure and Investment in US Manufacturing

Modern infrastructure and supportive government policies are essential for attracting manufacturing investment and fostering job growth.

Investment in Infrastructure and its Impact

The US needs significant investment in infrastructure—roads, bridges, energy grids, and broadband access—to support modern manufacturing.

- Government Funding and Private Investment: This requires a coordinated effort involving government funding and private sector investment to develop a robust and efficient infrastructure.

- Successful Infrastructure Projects: Investments in modernized ports and improved transportation networks are crucial for efficiently moving goods and materials.

- Infrastructure Requirements for Reshoring: Adequate infrastructure is a fundamental prerequisite for successfully attracting manufacturing investment and supporting reshoring initiatives.

Government Incentives and Tax Policies

Government incentives and favorable tax policies play a vital role in attracting manufacturing investment.

- Tax Breaks and Incentives: Tax breaks, subsidies, and other financial incentives can make the US a more attractive location for manufacturing companies.

- Effectiveness of Incentives in Stimulating Job Creation: The effectiveness of these incentives varies greatly depending on their design and implementation. Well-designed programs are more likely to generate job growth.

- Successful Government Programs: Government programs focused on workforce training and research and development can enhance the competitiveness of US manufacturers.

- Evaluating the Effectiveness of Government Incentives: Regular evaluation of these programs is crucial to ensuring that they are achieving their intended goals of attracting investment and creating jobs.

Conclusion

This article examined the feasibility of returning factory jobs to the US under Trump's policies, considering the interplay of trade policies, automation, labor costs, and infrastructure investment. While some policies aimed to boost domestic manufacturing, the complex nature of these factors reveals that reshoring isn't a simple solution. It depends heavily on long-term investments and strategies that go beyond just trade agreements. The reality is significantly more nuanced than a simple promise of bringing jobs back.

The long-term success of reshoring initiatives requires a holistic approach that addresses all these factors, including significant investment in education, infrastructure, and technology, along with carefully considered trade policies. Simply relying on tariffs or renegotiated trade deals is insufficient to overcome the challenges presented by automation and global competition.

Call to Action: Understanding the multifaceted challenges of bringing back factory jobs requires a nuanced approach. Further research and open discussion on effective reshoring strategies are vital to successfully revitalizing US manufacturing and securing high-quality American jobs. Let's continue the conversation on how to make reshoring a tangible reality for the long-term benefit of the US economy.

Featured Posts

-

Ignoring Hmrc Letters Potential Consequences For Uk Households

May 20, 2025

Ignoring Hmrc Letters Potential Consequences For Uk Households

May 20, 2025 -

Man Utd Striker Talks Agents Arrival Signals Accelerated Transfer

May 20, 2025

Man Utd Striker Talks Agents Arrival Signals Accelerated Transfer

May 20, 2025 -

Fenerbahce De Tadic Doenemi Sona Erdi Yeni Adresi Aciklandi

May 20, 2025

Fenerbahce De Tadic Doenemi Sona Erdi Yeni Adresi Aciklandi

May 20, 2025 -

Tampoy Perissotera Epeisodia Sto Mega Kathe Evdomada

May 20, 2025

Tampoy Perissotera Epeisodia Sto Mega Kathe Evdomada

May 20, 2025 -

Jose Mourinho Nun Tadic Ve Dzeko Yu Kullanma Sekli

May 20, 2025

Jose Mourinho Nun Tadic Ve Dzeko Yu Kullanma Sekli

May 20, 2025

Latest Posts

-

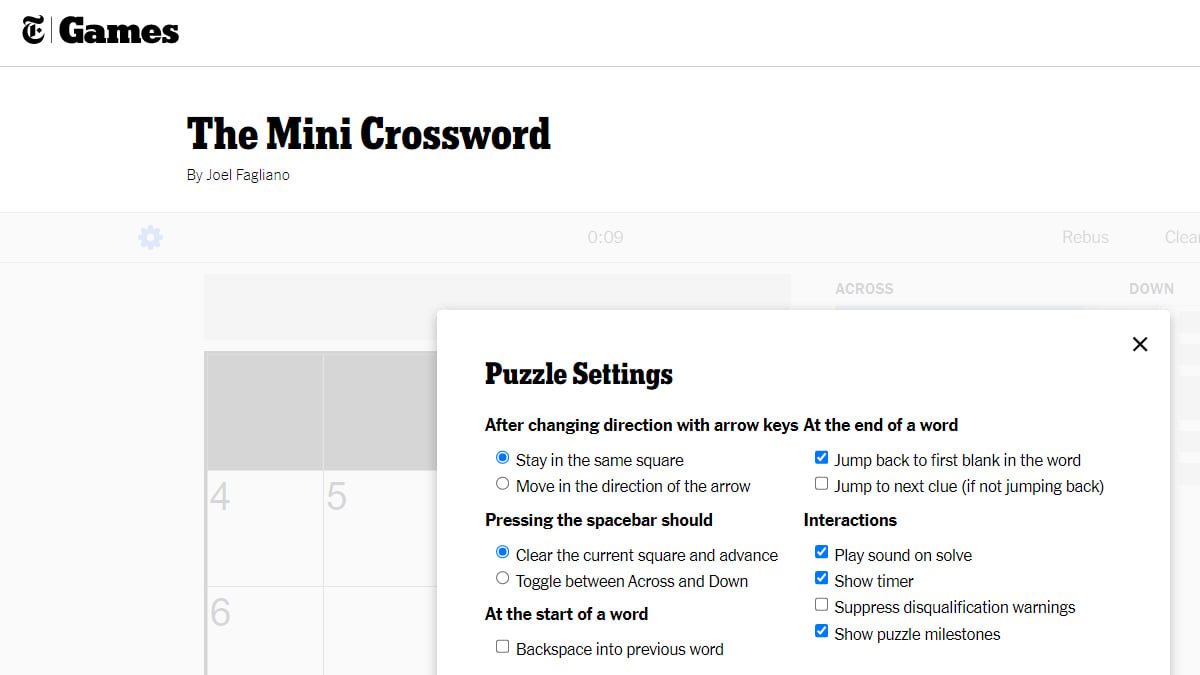

Complete Guide Nyt Mini Crossword Solutions March 24 2025

May 20, 2025

Complete Guide Nyt Mini Crossword Solutions March 24 2025

May 20, 2025 -

Nyt Mini Crossword Help Answers And Clues For March 24 2025

May 20, 2025

Nyt Mini Crossword Help Answers And Clues For March 24 2025

May 20, 2025 -

Nyt Mini Crossword Answers And Clues March 24 2025

May 20, 2025

Nyt Mini Crossword Answers And Clues March 24 2025

May 20, 2025 -

Nyt Mini Crossword Hints And Answers March 20 2025

May 20, 2025

Nyt Mini Crossword Hints And Answers March 20 2025

May 20, 2025 -

Solve The Nyt Mini Crossword Answers For March 24 2025

May 20, 2025

Solve The Nyt Mini Crossword Answers For March 24 2025

May 20, 2025