Case Study Addendum: BYD's Dominance In Electric Vehicle Battery Production

Table of Contents

BYD's Blade Battery Technology: A Game Changer

BYD's Blade Battery technology is a cornerstone of its success in EV battery production. This unique battery design boasts several advantages over traditional lithium-ion batteries, making it a game-changer in the industry. Its innovative structure offers:

-

Higher energy density: Compared to traditional cylindrical or prismatic cells, Blade Batteries pack more energy into the same space, leading to extended driving ranges for electric vehicles. This increased energy density is a significant factor in BYD's competitive advantage in the EV market.

-

Enhanced safety features: The Blade Battery's design inherently minimizes the risk of thermal runaway and fire, crucial for building consumer confidence in EV safety. This improved safety profile is a key selling point for BYD vehicles.

-

Cost-effective manufacturing process: BYD's manufacturing process for Blade Batteries is optimized for efficiency and cost reduction, leading to highly competitive pricing compared to other EV battery technologies. This allows BYD to offer compelling value to consumers.

-

Improved space utilization: The flat, blade-like form factor allows for better space utilization within the vehicle chassis, maximizing interior space and design flexibility for automakers.

The market reception to Blade Batteries has been overwhelmingly positive. Their integration into various BYD vehicle models, such as the Atto 3, Han, and Tang, has contributed significantly to their sales success and cemented BYD's reputation as a leading EV manufacturer. The improved range, safety, and affordability offered by Blade Batteries have significantly impacted BYD's competitiveness in the global EV market.

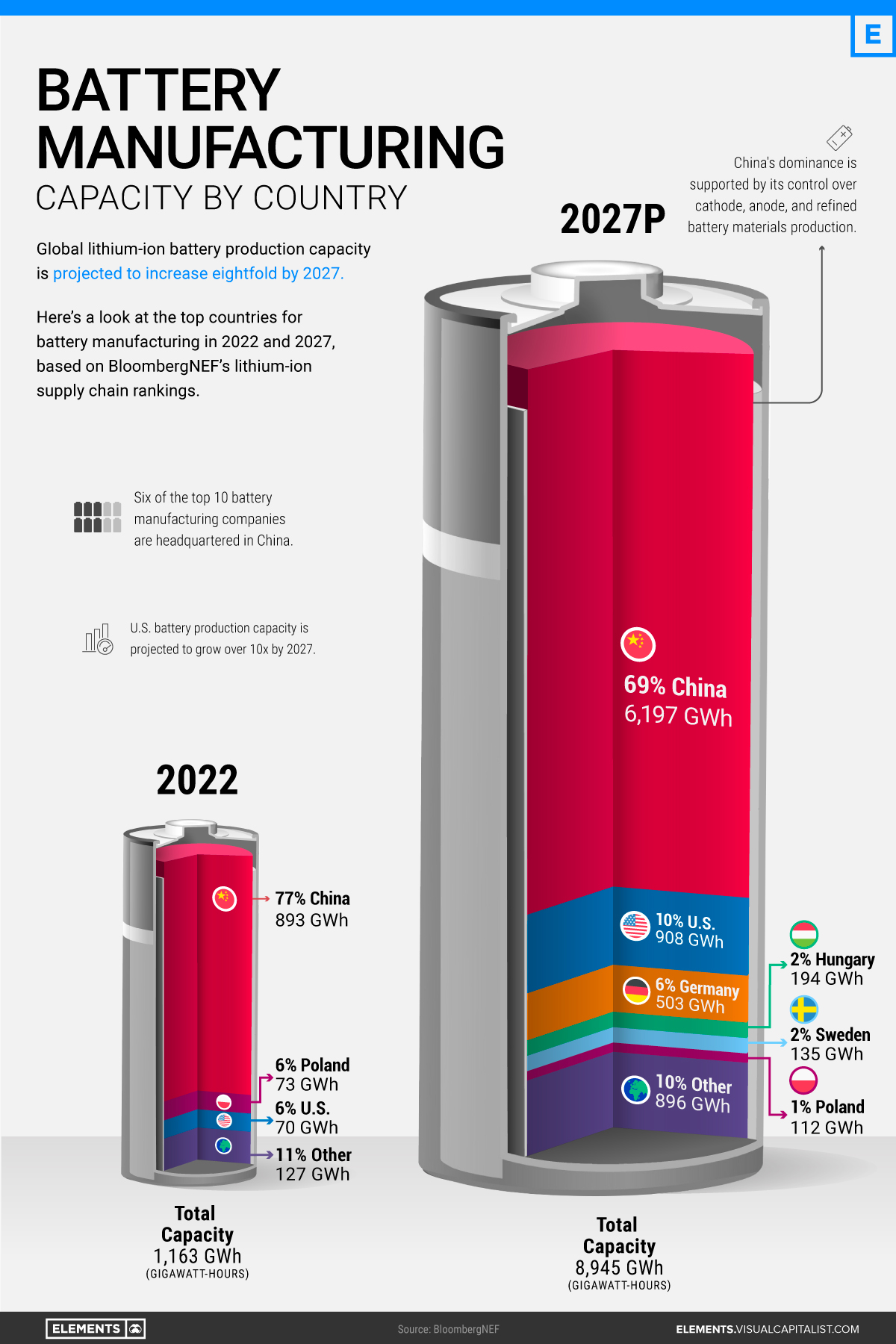

Vertical Integration: Controlling the Supply Chain

BYD's success in BYD Electric Vehicle Battery Production isn't just about the Blade Battery; it's also about their comprehensive vertical integration strategy. BYD controls a significant portion of its supply chain, from raw material sourcing to battery production and vehicle assembly. This strategic approach offers several key advantages:

-

Secure access to raw materials: By controlling its access to key raw materials, BYD minimizes its reliance on external suppliers, mitigating supply chain disruptions and ensuring consistent production. This resilience is critical in a rapidly evolving market.

-

Enhanced quality control: Vertical integration allows for rigorous quality control at every stage of the production process, ensuring consistent high quality in its batteries and vehicles. This contributes to superior product reliability and customer satisfaction.

-

Streamlined production: The streamlined processes resulting from vertical integration lead to significant cost savings and improved overall efficiency, making BYD's products more competitive in the market.

-

Reduced dependence on third-party suppliers: This reduces vulnerability to external factors affecting supplier performance and pricing. This contrasts sharply with many competitors who rely heavily on external battery suppliers, making them potentially more susceptible to supply chain shocks.

This vertical integration strategy provides BYD with significant cost control, superior operational efficiency, and a more resilient supply chain, giving it a substantial competitive edge over rivals that lack this level of control.

Aggressive Market Expansion and Global Reach

BYD's strategy for expanding its EV battery production and sales globally is ambitious and multifaceted. This involves:

-

Expansion into key EV markets: BYD is actively penetrating key EV markets in Europe, Asia, and North America, establishing a strong global presence.

-

Strategic partnerships: BYD is forging strategic partnerships with automotive manufacturers worldwide, leveraging their existing distribution networks and expertise to accelerate market penetration.

-

Establishment of new manufacturing facilities: BYD is investing heavily in building new manufacturing facilities globally to meet the growing demand for its batteries and electric vehicles. This proactive approach to capacity expansion ensures it can meet market needs efficiently.

-

Investment in R&D: Continuous investment in research and development for next-generation battery technology is crucial for maintaining BYD's leading position in the rapidly evolving EV industry.

While global expansion presents challenges, such as navigating diverse regulatory environments and adapting to regional preferences, BYD's strategic partnerships and investments are mitigating these risks. The company strategically leverages geographic advantages, including access to raw materials and skilled labor in certain regions, to optimize its manufacturing and distribution networks.

Sustainable Practices in BYD's Battery Production

BYD is also committed to sustainable manufacturing practices in its battery production. This includes:

-

Use of recycled materials: BYD incorporates recycled materials into its battery production process, minimizing waste and environmental impact.

-

Carbon footprint reduction: The company implements initiatives across its supply chain to reduce its carbon footprint and promote environmental responsibility.

-

Investment in battery recycling technology: BYD invests heavily in developing and deploying advanced battery recycling technologies, ensuring responsible end-of-life battery management.

-

Transparent reporting: BYD maintains a commitment to transparent reporting of its environmental performance, demonstrating its accountability and commitment to sustainability.

Sustainability is not just a trend; it's a crucial factor in the long-term viability and reputation of EV companies. BYD's proactive approach enhances its brand image and appeal to environmentally conscious consumers, further reinforcing its market position.

Conclusion

BYD's dominance in electric vehicle battery production is a testament to its strategic combination of cutting-edge Blade Battery technology, a vertically integrated supply chain, and a bold global expansion strategy. The Blade Battery's performance, safety, and cost-effectiveness have proven to be a game-changer. Its vertically integrated model ensures efficiency and resilience, while ambitious global growth solidifies BYD's position as an industry leader. Understanding BYD's success provides invaluable insights for other players in the EV battery industry, emphasizing the importance of innovation, strategic planning, and a commitment to sustainability. To delve deeper into the intricacies of BYD Electric Vehicle Battery Production and its future trajectory, explore relevant industry publications and official BYD reports.

Featured Posts

-

Geografichne Poshirennya Romskogo Naselennya V Ukrayini Statistichni Dani Ta Analiz

May 13, 2025

Geografichne Poshirennya Romskogo Naselennya V Ukrayini Statistichni Dani Ta Analiz

May 13, 2025 -

Ver Atalanta Vs Lecce En Vivo Online Serie A Jornada 34

May 13, 2025

Ver Atalanta Vs Lecce En Vivo Online Serie A Jornada 34

May 13, 2025 -

Record Breaking Temperatures Scorch La And Orange Counties Heatwave Impacts

May 13, 2025

Record Breaking Temperatures Scorch La And Orange Counties Heatwave Impacts

May 13, 2025 -

The Unending Ordeal Gaza Hostages And Their Families

May 13, 2025

The Unending Ordeal Gaza Hostages And Their Families

May 13, 2025 -

How To Train Your Dragon Live Action Near Miss With A Controversial Choice

May 13, 2025

How To Train Your Dragon Live Action Near Miss With A Controversial Choice

May 13, 2025

Latest Posts

-

Pieterburen Seal Rescue Center A 50 Year Legacy Ends With Final Seal Release

May 13, 2025

Pieterburen Seal Rescue Center A 50 Year Legacy Ends With Final Seal Release

May 13, 2025 -

Closure Of Pieterburen Seal Rescue Center 50 Years Of Service Concludes

May 13, 2025

Closure Of Pieterburen Seal Rescue Center 50 Years Of Service Concludes

May 13, 2025 -

Last Seals Released As Pieterburen Rescue Center Ends 50 Year Mission

May 13, 2025

Last Seals Released As Pieterburen Rescue Center Ends 50 Year Mission

May 13, 2025 -

Pieterburen Seal Center Closes Final Seals Released After 50 Years

May 13, 2025

Pieterburen Seal Center Closes Final Seals Released After 50 Years

May 13, 2025 -

Recent Developments Partynextdoor Apologizes To Tory Lanez

May 13, 2025

Recent Developments Partynextdoor Apologizes To Tory Lanez

May 13, 2025