Challenges And Advancements In Automated Visual Inspection Of Lyophilized Vials

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Vials

Automated visual inspection systems for lyophilized vials face several complex hurdles. Overcoming these challenges is crucial for widespread adoption and reliable quality control.

Complex Defect Detection

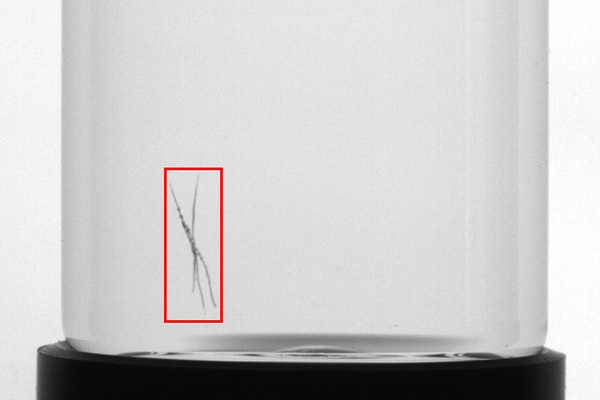

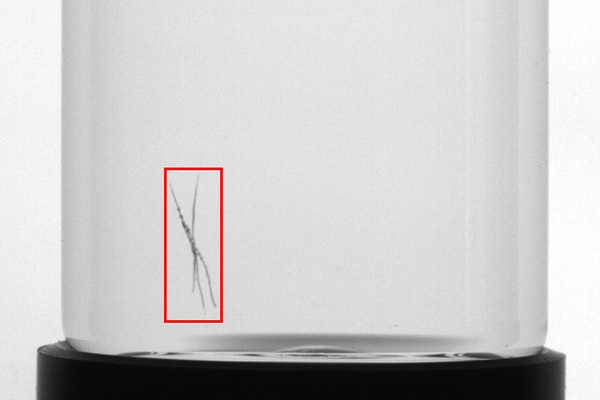

Detecting subtle defects in lyophilized vials presents a significant challenge. These defects can be incredibly difficult to identify:

- Cracks: Microscopic cracks in the vial glass can compromise sterility and product integrity. Automated systems must be sensitive enough to detect these, even when partially obscured.

- Particulate Matter: Foreign particles within the vial can be detrimental to patient safety. Identifying these against the often-translucent background of the lyophilized product requires sophisticated image analysis.

- Fill Level Variations: Inconsistent fill levels indicate potential process inconsistencies. Accurate measurement and detection require precise image analysis algorithms.

- Seal Integrity: The seal on the vial must be perfect. Automated systems must reliably check for any imperfections that could lead to contamination.

The shape and material of the vials themselves add complexity. Variations in glass thickness, color, and surface finish can confound image analysis algorithms. Furthermore, variations in the lyophilization process itself—resulting in differences in cake appearance, for example—can further complicate defect detection.

High-Throughput Requirements

Pharmaceutical manufacturing operates at enormous scales. Automated visual inspection systems for lyophilized vials must keep pace with these high-throughput demands. This necessitates:

- High-Speed Inspection: Systems need to inspect vials at speeds consistent with high-volume production lines, without sacrificing accuracy.

- Speed vs. Accuracy Trade-off: Balancing speed and accuracy is a critical design consideration. Increasing speed often necessitates compromises in the level of detail that can be analyzed.

- System Integration: Seamless integration with existing manufacturing equipment and production line workflows is vital for efficient deployment and minimal disruption. This involves careful consideration of data transfer protocols and automation systems.

False Positives and False Negatives

Minimizing errors is paramount in automated visual inspection. Both false positives (rejecting good vials) and false negatives (accepting defective vials) have significant consequences:

- False Positives: Lead to wasted product, increased costs, and reduced production efficiency.

- False Negatives: Pose a serious risk to patient safety and can have devastating repercussions.

Robust algorithms and sophisticated image processing techniques are crucial to minimizing these errors. Rigorous quality control procedures and comprehensive system validation are essential steps to ensure system reliability and reduce the risk of both false positives and false negatives.

Advancements in Automated Visual Inspection of Lyophilized Vials

Significant advancements are transforming the capabilities of automated visual inspection systems for lyophilized vials:

Advanced Imaging Technologies

Several advanced imaging technologies are improving defect detection capabilities:

- High-Resolution Cameras: These provide detailed images, enabling the detection of even the smallest defects.

- Advanced Lighting Techniques: Structured light and multispectral imaging techniques enhance contrast and reveal defects otherwise invisible with conventional lighting.

- 3D Imaging: 3D imaging provides a complete spatial representation of the vial, allowing for comprehensive defect analysis and the detection of defects hidden from 2D imaging.

AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are revolutionizing automated visual inspection:

- Image Analysis: AI algorithms analyze images to identify and classify defects with greater accuracy and speed than traditional methods.

- Adaptive Learning: ML allows systems to learn and adapt to variations in vial appearance and lyophilization processes, improving their performance over time.

- Deep Learning: Deep learning algorithms, a subset of ML, are particularly effective at identifying complex patterns and subtle defects in images.

Robotic Automation and Integration

Robotic automation plays a crucial role in improving the efficiency and reliability of automated visual inspection:

- Automated Handling: Robots automate the handling and presentation of vials to the inspection system, minimizing human interaction and reducing the risk of errors.

- Increased Throughput: Robotic automation significantly increases throughput, allowing for faster inspection rates and higher production volumes.

- System Integration: Robotic systems can be seamlessly integrated with existing manufacturing equipment and data management systems.

Conclusion

Automated visual inspection of lyophilized vials presents significant challenges relating to defect detection, high-throughput requirements, and minimizing false positives and negatives. However, the rapid advancements in imaging technology, AI, and robotics are driving substantial improvements in accuracy, speed, and efficiency. The implementation of these advanced systems is crucial for ensuring product quality and meeting the demands of the pharmaceutical industry. Investing in advanced solutions for automated visual inspection of lyophilized vials is no longer a luxury but a necessity. Learn more about the latest technologies and how they can improve your quality control processes. Contact us today to discuss your needs and explore how automated visual inspection of lyophilized vials can benefit your pharmaceutical operation.

Featured Posts

-

Who Is Manon Fiorot A Deep Dive Into The French Ufc Fighter

May 11, 2025

Who Is Manon Fiorot A Deep Dive Into The French Ufc Fighter

May 11, 2025 -

Virginia Giuffre Hvordan Skandalen Pavirket Prins Andrew Og Kongefamilien

May 11, 2025

Virginia Giuffre Hvordan Skandalen Pavirket Prins Andrew Og Kongefamilien

May 11, 2025 -

Win Tickets Tales From The Track Event

May 11, 2025

Win Tickets Tales From The Track Event

May 11, 2025 -

The Short Lived Bundesliga Dream Holstein Kiels Relegation

May 11, 2025

The Short Lived Bundesliga Dream Holstein Kiels Relegation

May 11, 2025 -

Efficient Asylum Shelter Management A E1 Billion Cost Saving Potential

May 11, 2025

Efficient Asylum Shelter Management A E1 Billion Cost Saving Potential

May 11, 2025