Cost-Cutting Measures Surge As U.S. Companies Face Tariff Woes

Table of Contents

Impact of Tariffs on U.S. Businesses

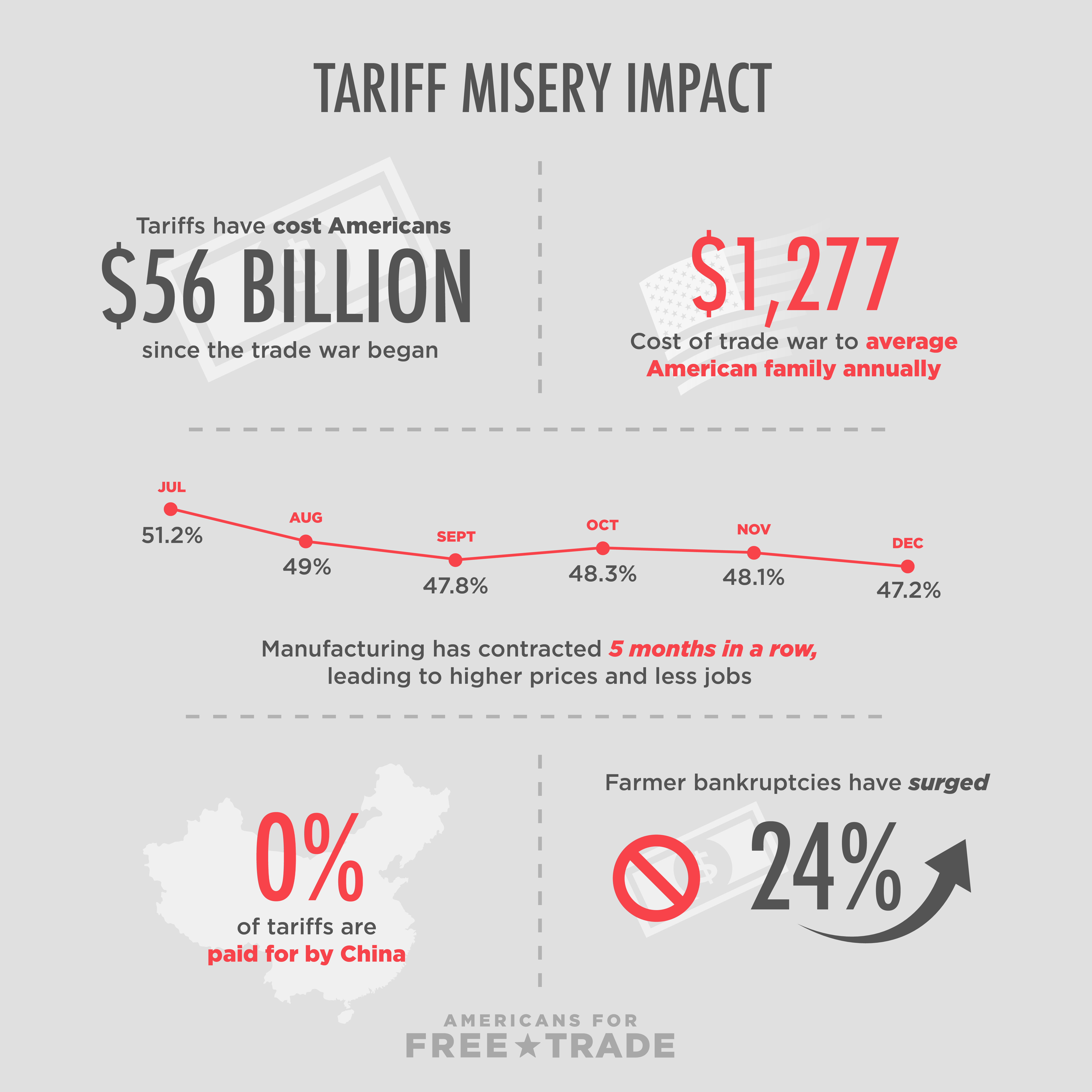

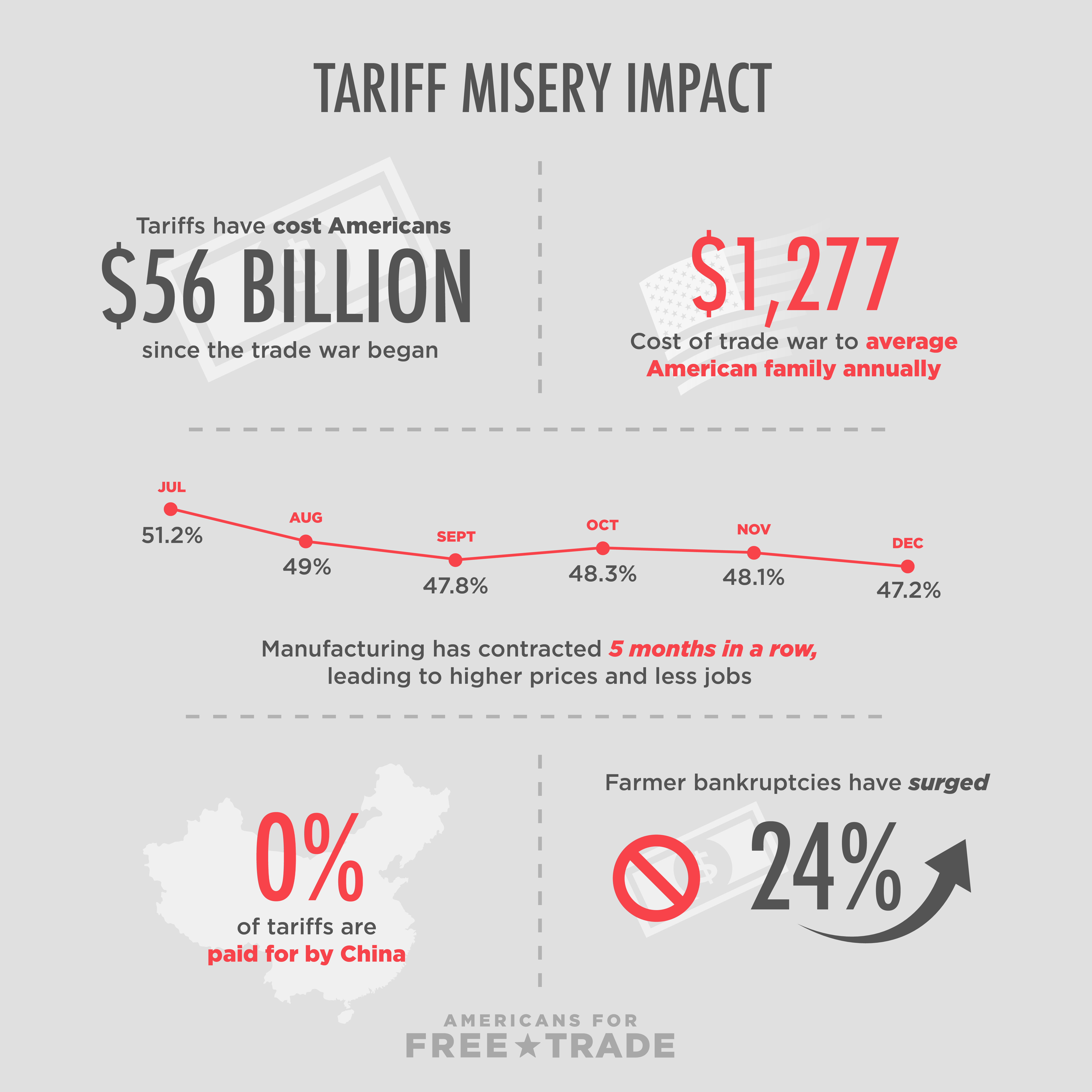

The imposition of tariffs has had a profound and multifaceted impact on American businesses across various sectors. Increased import costs, a direct consequence of tariffs, have created a ripple effect throughout the economy. Manufacturing, agriculture, and retail sectors, among others, are feeling the pinch.

Statistics paint a stark picture. For example, a recent study by the [Insert Source and Citation] revealed a [Insert Percentage]% increase in import costs for [Specific Industry] since the implementation of tariffs. This has led to a significant decline in profit margins and reduced competitiveness in global markets.

- Rising input costs for raw materials and components: Tariffs increase the price of imported materials, impacting production costs and profitability.

- Reduced competitiveness in global markets: Higher prices make U.S. goods less attractive to international buyers, leading to a decline in exports.

- Increased prices for consumers: Businesses often pass on increased costs to consumers, leading to inflation and reduced consumer spending.

- Loss of profit margins: The squeeze on profitability forces businesses to seek ways to cut costs to maintain viability.

- Supply chain disruptions: Tariffs can disrupt established supply chains, forcing businesses to search for alternative suppliers and potentially incurring higher transportation costs.

Strategies for Reducing Operational Costs

Faced with these challenges, U.S. businesses are aggressively pursuing various cost-cutting strategies to mitigate the impact of tariffs. These strategies can be broadly categorized into operational efficiency improvements, supply chain adjustments, and workforce management changes.

Automation and Technological Upgrades

Many companies are investing in automation and technological upgrades to enhance efficiency and reduce reliance on labor. This shift involves implementing robotics, artificial intelligence (AI), and sophisticated software solutions to streamline processes.

- Reduced labor costs through automation: Automating repetitive tasks reduces the need for manual labor, lowering payroll expenses.

- Increased productivity and output: Automation often leads to higher output with improved speed and accuracy.

- Improved quality control: Automated systems can maintain consistent quality, minimizing errors and waste.

- Potential for long-term cost savings: While initial investment can be significant, automation can offer substantial long-term cost savings.

Supply Chain Optimization

Optimizing the supply chain is crucial for mitigating tariff risks. Strategies include reshoring (bringing production back to the U.S.), nearshoring (moving production to nearby countries), or diversifying supply chains to reduce reliance on single sources.

- Reducing reliance on single-source suppliers: Diversification minimizes the impact of disruptions from any single supplier.

- Exploring alternative sourcing options (domestic or international): Finding suppliers in countries with more favorable trade agreements can help mitigate tariff impacts.

- Negotiating better terms with suppliers: Stronger relationships and bulk purchasing can lead to better pricing and payment terms.

- Implementing inventory management techniques: Efficient inventory management reduces storage costs and minimizes waste.

Restructuring and Workforce Reductions

In some cases, restructuring and workforce reductions become necessary, albeit difficult, cost-cutting measures. While ethically sensitive, these steps might be unavoidable for survival.

- Layoffs and downsizing: Reducing workforce size can significantly lower labor costs.

- Wage freezes or reductions: These measures, although unpopular, can help control labor expenses.

- Hiring freezes: Halting new hiring helps maintain existing staffing levels without adding to payroll.

- Voluntary separation programs: Offering incentives for employees to voluntarily leave can be a more humane approach to workforce reduction.

Negotiating with Suppliers and Reducing Material Costs

Businesses are also actively negotiating better terms with suppliers and exploring ways to reduce material costs.

- Consolidating suppliers: Working with fewer, larger suppliers can often lead to better pricing.

- Implementing stricter quality control: Minimizing defects and waste reduces material consumption.

- Seeking bulk discounts: Purchasing in larger quantities can result in significant cost savings.

- Exploring alternative, cheaper materials: Switching to less expensive, yet suitable, materials can lower production costs.

Long-Term Implications and Adaptation

The long-term consequences of these cost-cutting measures are multifaceted. While they can enhance efficiency and competitiveness in the short-term, they also have potential drawbacks.

- Increased efficiency and competitiveness: Effective cost-cutting can improve a company's bottom line and make it more resilient.

- Potential for job displacement and social impact: Automation and workforce reductions can lead to job losses and social unrest.

- Necessity for employee retraining and upskilling: The shift towards automation requires workers to adapt and develop new skills.

- Long-term impact on economic growth: The widespread adoption of cost-cutting measures can have a significant impact on economic growth and stability.

Conclusion

The surge in cost-cutting measures demonstrates the significant challenges U.S. companies face due to tariff woes. From automating processes to restructuring operations, businesses are aggressively seeking solutions to maintain profitability in this turbulent environment. While some measures might involve difficult decisions, long-term adaptation and strategic planning are crucial for survival and future success. Understanding the implications of tariffs and proactively implementing effective cost-cutting measures is vital for navigating the current economic climate and ensuring the long-term health of your business. Don't wait until it's too late – explore effective cost-cutting strategies today to mitigate the impact of tariffs on your bottom line.

Featured Posts

-

The Becciu Case A Deeper Look At Allegations Of Unfair Proceedings

Apr 29, 2025

The Becciu Case A Deeper Look At Allegations Of Unfair Proceedings

Apr 29, 2025 -

Nyt Spelling Bee March 14 2025 Clues Answers And Pangram

Apr 29, 2025

Nyt Spelling Bee March 14 2025 Clues Answers And Pangram

Apr 29, 2025 -

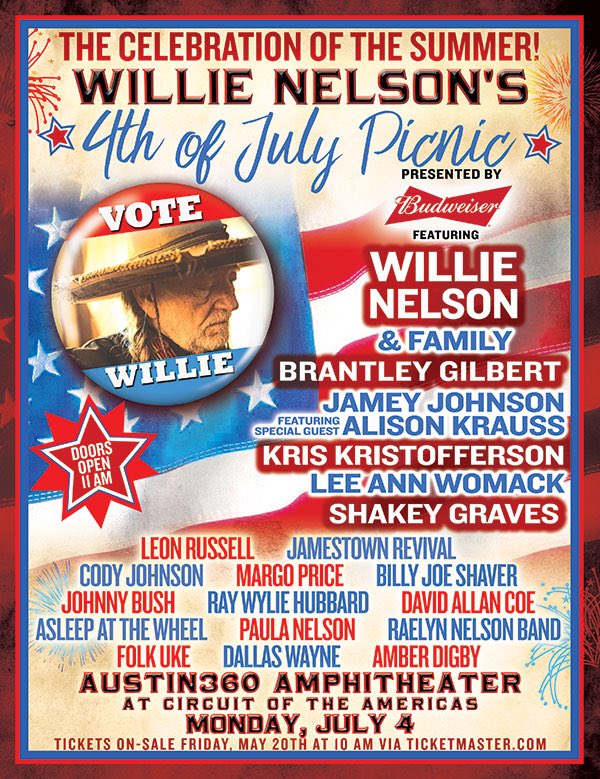

Get Your Tickets Now Willie Nelsons 4th Of July Picnic Is Back In Texas

Apr 29, 2025

Get Your Tickets Now Willie Nelsons 4th Of July Picnic Is Back In Texas

Apr 29, 2025 -

Tgi Ag Feiert In Kitzbuehel Blick In Die Zukunft

Apr 29, 2025

Tgi Ag Feiert In Kitzbuehel Blick In Die Zukunft

Apr 29, 2025 -

Capital Summertime Ball 2025 Tickets The Ultimate Guide To Purchase

Apr 29, 2025

Capital Summertime Ball 2025 Tickets The Ultimate Guide To Purchase

Apr 29, 2025

Latest Posts

-

Fox News And Conor Mc Gregor A Look At Their Relationship

May 12, 2025

Fox News And Conor Mc Gregor A Look At Their Relationship

May 12, 2025 -

Chicago Bulls Vs New York Knicks Latest Injury Reports

May 12, 2025

Chicago Bulls Vs New York Knicks Latest Injury Reports

May 12, 2025 -

Find The Ny Knicks Vs Cleveland Cavaliers Game Time Tv Channel And Live Streaming Information

May 12, 2025

Find The Ny Knicks Vs Cleveland Cavaliers Game Time Tv Channel And Live Streaming Information

May 12, 2025 -

Knicks Vs Bulls Betting Preview Expert Predictions Odds Comparison And Analysis Feb 20 2025

May 12, 2025

Knicks Vs Bulls Betting Preview Expert Predictions Odds Comparison And Analysis Feb 20 2025

May 12, 2025 -

February 20 2025 Knicks Vs Bulls Predictions Odds And Betting Tips

May 12, 2025

February 20 2025 Knicks Vs Bulls Predictions Odds And Betting Tips

May 12, 2025