Efficient Automated Visual Inspection Of Lyophilized Vials: Addressing Key Challenges

Table of Contents

Challenges in Manual Visual Inspection of Lyophilized Vials

Manual inspection of lyophilized vials presents numerous limitations that significantly impact efficiency and accuracy. Human inspectors face challenges in maintaining consistent performance over long periods, leading to inconsistencies in defect detection. The subjective nature of visual assessment results in high rates of both false positives (rejecting acceptable vials) and false negatives (accepting defective vials). This can have serious consequences, impacting product quality and potentially patient safety.

- High false-positive and false-negative rates: Subjectivity in visual assessment leads to inconsistencies in defect identification.

- Operator fatigue leading to decreased accuracy: Prolonged visual inspection tasks cause fatigue, diminishing the inspector's concentration and accuracy.

- Bottlenecks in production due to slow inspection speeds: Manual inspection significantly slows down production lines, hindering throughput and overall efficiency.

- Difficulty in maintaining consistent quality standards across different inspectors: Variations in individual inspector's experience and perception result in inconsistent quality control.

- Increased labor costs: The high personnel costs associated with manual inspection contribute to overall manufacturing expenses. The growing demand for higher inspection standards further exacerbates this issue.

Benefits of Automated Visual Inspection Systems

Automated visual inspection systems offer a compelling solution to the limitations of manual methods. By leveraging advanced technologies, these systems significantly enhance speed, accuracy, and consistency in lyophilized vial inspection. The transition to automated systems translates into several key benefits:

- Enhanced accuracy and precision in defect detection: Automated systems can detect subtle defects often missed by human inspectors, ensuring higher product quality. This includes identifying cracks, particulate matter, fill level discrepancies, and other critical imperfections.

- Increased throughput and faster processing times: Automated systems significantly accelerate inspection speed, leading to increased production efficiency and reduced bottlenecks.

- Objective and consistent inspection results: Automation eliminates the subjectivity inherent in manual inspection, providing objective and reliable results regardless of the operator.

- Reduced labor costs and improved efficiency: Automated systems reduce reliance on manual labor, leading to cost savings and increased overall efficiency in the long run.

- Improved data management and traceability: Automated systems capture and store detailed inspection data, enhancing traceability and facilitating quality control analysis.

Key Technological Advancements in Automated Lyophilized Vial Inspection

Recent advancements in machine vision, artificial intelligence (AI), and image processing have revolutionized automated lyophilized vial inspection. These technologies enable the rapid and accurate detection of even minute defects.

- High-resolution cameras for detailed image capture: Sophisticated cameras capture high-resolution images of each vial, providing detailed visual information for analysis.

- Advanced algorithms for defect identification and classification: AI-powered algorithms analyze images to identify and classify various defects with high precision. These algorithms are trained on vast datasets of vial images, improving their accuracy over time.

- Integration with existing production lines: Modern automated systems are designed to seamlessly integrate with existing pharmaceutical manufacturing lines, minimizing disruption to workflows.

- Data analytics for process optimization and quality control: Automated systems generate detailed data reports that can be used to optimize production processes and improve overall quality control. This data provides valuable insights for continuous improvement.

- Different system types: Automated systems can be implemented as in-line systems integrated directly into the production line for continuous inspection, or as offline systems for post-production inspection of batches of vials.

Addressing Specific Challenges in Automated Lyophilized Vial Inspection

While automated systems offer significant advantages, certain challenges need to be addressed for successful implementation.

- Dealing with variations in lyophilized product appearance: Variations in the appearance of lyophilized products due to differences in formulation or processing can affect the accuracy of automated inspection. Advanced image processing techniques and specialized algorithms are used to mitigate these variations.

- Minimizing the impact of ambient lighting on inspection results: Fluctuations in ambient lighting can impact image quality and the accuracy of defect detection. Controlled lighting environments and sophisticated image processing algorithms are crucial to minimize these effects.

- Ensuring compliance with regulatory requirements: Automated systems must adhere to stringent regulatory requirements such as GMP (Good Manufacturing Practices) and 21 CFR Part 11. Validation and qualification processes are essential to ensure compliance.

- Implementing robust quality control measures: Regular calibration, maintenance, and performance verification are necessary to maintain the accuracy and reliability of automated systems.

Optimizing Lyophilized Vial Inspection with Automated Solutions

Automated visual inspection offers significant advantages over manual methods, improving accuracy, speed, and consistency while reducing labor costs. Addressing the challenges discussed above through careful system design and implementation is crucial for successful integration into pharmaceutical manufacturing processes. Investment in efficient automated visual inspection systems translates to long-term benefits, including enhanced product quality, improved regulatory compliance, and increased profitability. Invest in efficient automated visual inspection of lyophilized vials today and enhance your pharmaceutical quality control. Learn more about optimizing your lyophilized vial inspection process with automated solutions. Contact us today!

Featured Posts

-

Plei Of Nba Odigos Gia Ta Zeygaria Kai Tis Imerominies Agonon

May 11, 2025

Plei Of Nba Odigos Gia Ta Zeygaria Kai Tis Imerominies Agonon

May 11, 2025 -

Grown Ups 2 Behind The Scenes And Production Details

May 11, 2025

Grown Ups 2 Behind The Scenes And Production Details

May 11, 2025 -

How Adam Sandlers Netflix Movies Led To Meeting His Wife

May 11, 2025

How Adam Sandlers Netflix Movies Led To Meeting His Wife

May 11, 2025 -

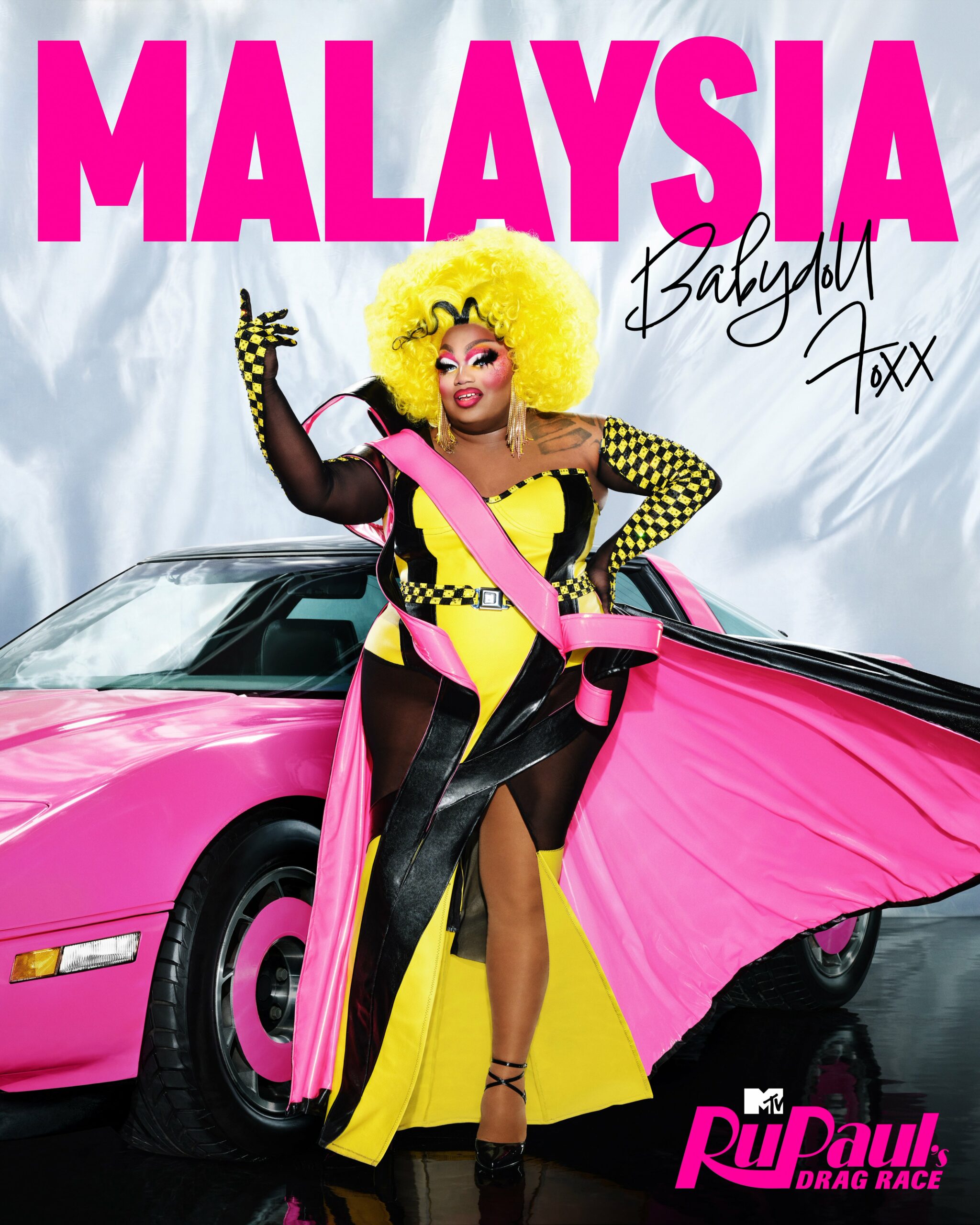

Ru Pauls Drag Race S17 E13 Drag Baby Mamas Preview Family Drama

May 11, 2025

Ru Pauls Drag Race S17 E13 Drag Baby Mamas Preview Family Drama

May 11, 2025 -

Where To Start A Business Identifying The Countrys Top Locations

May 11, 2025

Where To Start A Business Identifying The Countrys Top Locations

May 11, 2025