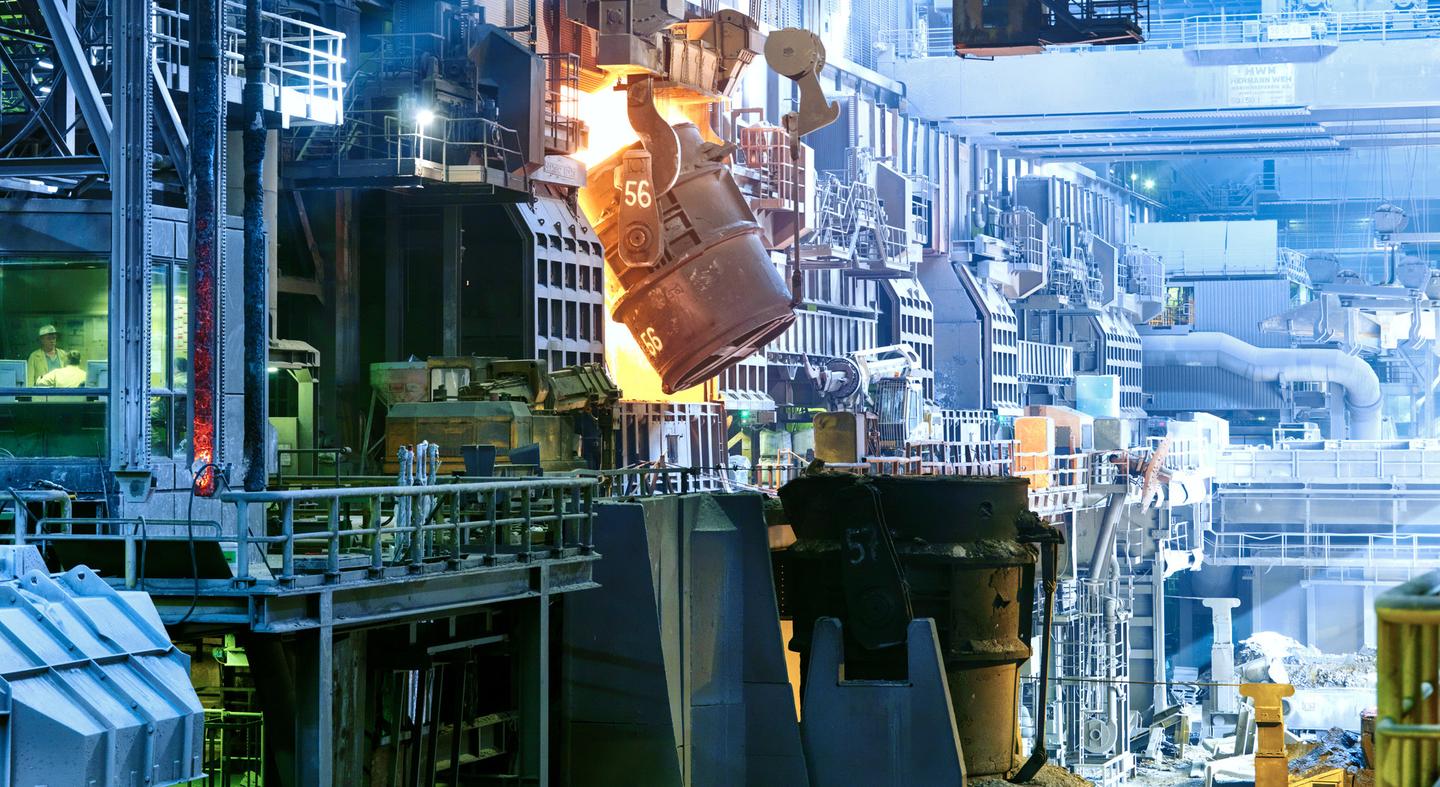

Eramet's EraLow: A Decarbonization Breakthrough For The Steel Industry

Table of Contents

Understanding Eramet's eraLow and its Production Process

What is eraLow?

Eramet's eraLow is a groundbreaking low-carbon manganese alloy designed to significantly reduce the carbon footprint of steel production. Manganese is a crucial alloying element in steelmaking, impacting its strength, hardness, and weldability. Traditional manganese production methods are energy-intensive and contribute substantially to CO2 emissions. eraLow offers a superior alternative, boasting several key advantages:

- Reduced CO2 emissions: Compared to traditional manganese alloys, eraLow boasts a significantly lower carbon footprint, contributing to a greener steel production process.

- Enhanced steel quality: eraLow's unique composition enhances the quality and performance characteristics of the resulting steel, leading to improved mechanical properties.

- Improved energy efficiency: Using eraLow can lead to improvements in the overall energy efficiency of steel production, further minimizing environmental impact.

- Circular economy potential: Eramet is committed to exploring the potential for integrating eraLow into circular economy models, facilitating recycling and reducing waste.

The Sustainable Production Method of eraLow

Eramet employs innovative and sustainable methods to produce eraLow, focusing on minimizing its environmental impact throughout the entire lifecycle. This commitment to sustainability is a key differentiator:

- Renewable energy utilization: Eramet leverages renewable energy sources to power its production facilities, reducing reliance on fossil fuels.

- Carbon capture and storage (CCS): The company actively explores and implements CCS technologies to capture and store CO2 emissions generated during the production process.

- Process optimization: Eramet continuously optimizes its energy-intensive processes to maximize efficiency and minimize waste.

- Resource minimization: The production process is designed to minimize resource consumption and waste generation, promoting a circular economy approach.

The Impact of eraLow on Steel Decarbonization

Significant CO2 Emission Reductions

The use of eraLow promises substantial reductions in CO2 emissions from steel production. Preliminary data suggests impressive results:

- Percentage reduction: Eramet's internal studies indicate a significant percentage reduction in CO2 emissions per ton of steel produced when using eraLow compared to traditional methods. Specific figures will be released as data becomes publicly available.

- Industry benchmarks: These emission reductions are expected to surpass industry benchmarks and contribute significantly towards meeting global climate targets.

- Long-term potential: The widespread adoption of eraLow across the steel industry has the potential to drastically reduce global CO2 emissions from steel production in the long term.

Enhancing Steel Quality and Performance

Beyond its environmental benefits, eraLow also enhances the quality and performance characteristics of steel:

- Improved mechanical properties: The use of eraLow results in steel with improved strength, durability, and toughness.

- Enhanced processability: Steel produced with eraLow exhibits better weldability and formability, making it easier to manufacture and process.

- New applications: The superior properties of eraLow-enhanced steel open up new application possibilities, including lightweighting and high-strength steel components for various industries (automotive, construction, etc.).

Challenges and Future Prospects of eraLow

Addressing the Challenges of Large-Scale Adoption

Despite its significant potential, the widespread adoption of eraLow faces certain challenges:

- Cost competitiveness: Ensuring the cost-effectiveness of eraLow compared to traditional manganese alloys is crucial for large-scale adoption.

- Production scalability: Scaling up production capacity to meet the growing demand from the steel industry requires significant investment and infrastructure development.

- Stakeholder engagement: Educating and engaging all stakeholders—steel producers, manufacturers, and policymakers—is essential to ensure widespread acceptance and adoption.

Future Research and Development

Eramet remains committed to ongoing research and development efforts to further improve eraLow and expand its applications:

- Advanced CO2 reduction: Further research focuses on developing even more efficient technologies for reducing CO2 emissions throughout the production process.

- New alloy development: The company is exploring the development of new alloys based on the eraLow platform, potentially offering further improvements in steel quality and sustainability.

- Industry collaboration: Eramet actively collaborates with research institutions and industry partners to accelerate the development and adoption of eraLow.

Conclusion

Eramet's eraLow represents a significant leap forward in the decarbonization of the steel industry. By offering a low-carbon alternative to traditional manganese alloys, eraLow enables steel producers to significantly reduce their carbon footprint while enhancing steel quality and performance. While challenges remain in scaling up production and achieving widespread adoption, the potential benefits of eraLow for sustainable steel production are undeniable. The future of steelmaking is undoubtedly intertwined with innovative solutions like eraLow, paving the way for a greener and more sustainable future. Learn more about Eramet's commitment to sustainable steel production and explore the possibilities of eraLow for your own decarbonization strategy. Invest in a greener future with eraLow.

Featured Posts

-

Where To Go In May A Month Of Travel Inspiration

May 14, 2025

Where To Go In May A Month Of Travel Inspiration

May 14, 2025 -

Eurojackpotin 40 000 E Voitto Suomeen Onnen Lipun Tarina

May 14, 2025

Eurojackpotin 40 000 E Voitto Suomeen Onnen Lipun Tarina

May 14, 2025 -

Fa Cup Awoniyi In Line For Starting Xi

May 14, 2025

Fa Cup Awoniyi In Line For Starting Xi

May 14, 2025 -

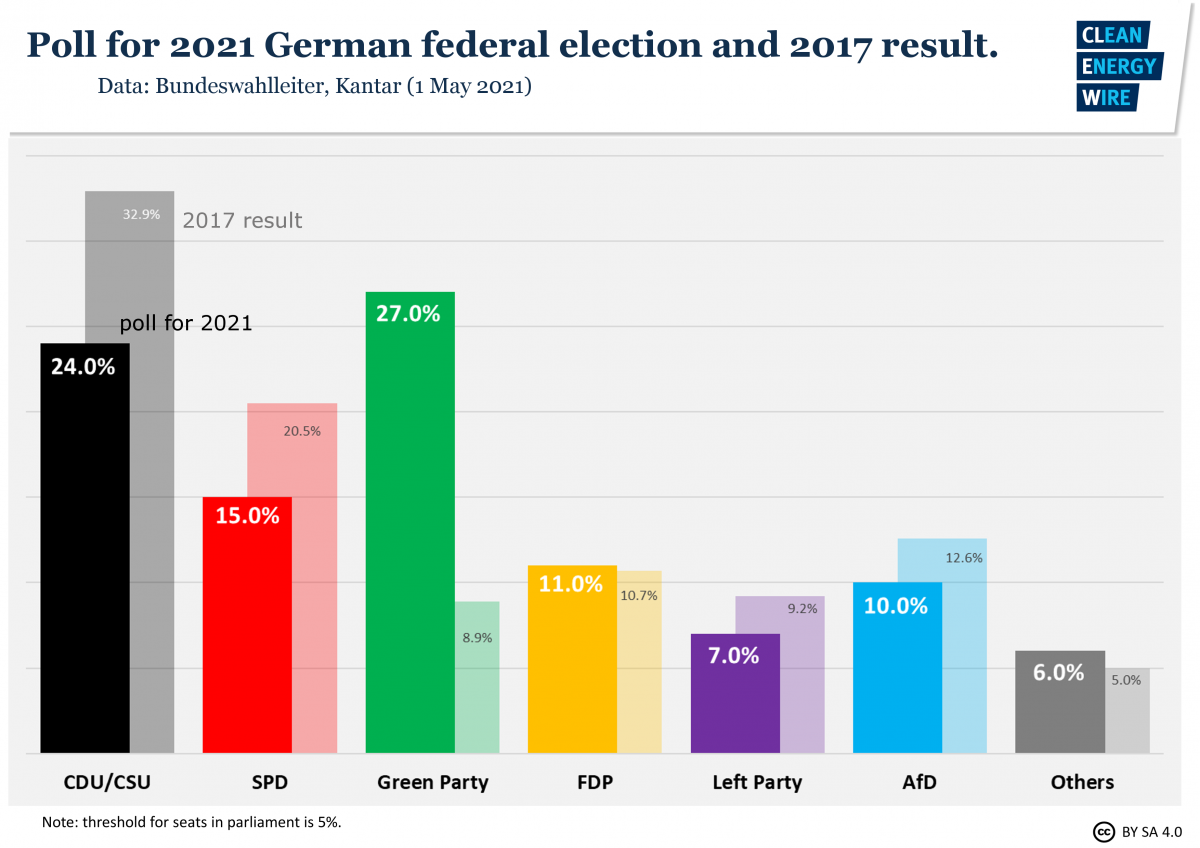

The Upcoming German Election A Crucial Turning Point

May 14, 2025

The Upcoming German Election A Crucial Turning Point

May 14, 2025 -

Trump Tariffs And Their Impact On The Fintech Ipo Market An Affirm Afrm Perspective

May 14, 2025

Trump Tariffs And Their Impact On The Fintech Ipo Market An Affirm Afrm Perspective

May 14, 2025

Latest Posts

-

Following Breakup Claims Kanye West And Bianca Censori Enjoy Dinner In Spain

May 14, 2025

Following Breakup Claims Kanye West And Bianca Censori Enjoy Dinner In Spain

May 14, 2025 -

Kanye West And Bianca Censori A New Chapter Spotted With Look Alike In La

May 14, 2025

Kanye West And Bianca Censori A New Chapter Spotted With Look Alike In La

May 14, 2025 -

Kanye Wests Wife Bianca Censori Shows Off Figure In Bra And Thong

May 14, 2025

Kanye Wests Wife Bianca Censori Shows Off Figure In Bra And Thong

May 14, 2025 -

Is It Back On Kanye West And Bianca Censori Spotted Dining In Spain

May 14, 2025

Is It Back On Kanye West And Bianca Censori Spotted Dining In Spain

May 14, 2025 -

Kanye West And Bianca Censori Spain Dinner Date After Split Claims

May 14, 2025

Kanye West And Bianca Censori Spain Dinner Date After Split Claims

May 14, 2025