Eramet's EraLow: A Key Step In Steel Industry Decarbonization

Table of Contents

Understanding Eramet's eraLow Process

Eramet's eraLow process is a groundbreaking technology focused on the sustainable production of manganese alloys, crucial components in steelmaking. This innovative approach significantly reduces the carbon footprint associated with traditional manganese production methods. The core technology behind eraLow centers on optimizing energy efficiency and leveraging renewable energy sources throughout the production chain. This commitment to sustainable production results in several key advantages:

- Significantly reduced CO2 emissions: Compared to traditional methods, eraLow boasts a drastically lower CO2 emission profile, contributing directly to the reduction of greenhouse gas emissions in the steel industry. This makes it a vital tool for companies aiming to meet their ESG (environmental, social, and governance) targets.

- Utilizes renewable energy sources: Eramet actively integrates renewable energy sources into the eraLow process, minimizing reliance on fossil fuels and further decreasing its environmental impact. This commitment aligns perfectly with the increasing global focus on clean energy and a circular economy.

- Improved energy efficiency: The eraLow process is engineered for optimal energy efficiency, leading to lower operational costs and a reduced environmental footprint. This makes it a financially viable option for steel producers while simultaneously contributing to sustainability goals.

- Production of high-quality manganese alloys: The process delivers high-quality manganese alloys essential for the production of various types of steel, ensuring both sustainability and performance are met. These alloys are crucial for enhancing steel's strength and durability.

- Contribution to the circular economy: Eramet's commitment extends to responsible sourcing of raw materials and minimizing waste throughout the eraLow process, actively contributing to the principles of a circular economy. This approach ensures the long-term viability and sustainability of the entire production cycle.

The Role of Manganese in Steel Decarbonization

Manganese is a critical alloying element in steel production, significantly impacting its strength, durability, and workability. Traditional manganese production methods, however, contribute substantially to the steel industry's overall carbon emissions. Eramet's eraLow process directly addresses this challenge by providing a sustainable alternative.

- Manganese as a key alloying element: Manganese's role in enhancing steel properties is undeniable, making its sustainable production a priority for a greener steel industry. It is an essential component in creating high-strength, low-carbon steels.

- Reducing the carbon footprint of steel: By employing the eraLow process, steel manufacturers can significantly reduce the overall carbon footprint of their products, enabling them to meet increasingly stringent environmental regulations and market demands.

- Enabling high-strength, low-carbon steel production: The high-quality manganese alloys produced by eraLow facilitate the creation of high-strength, low-carbon steels, ideal for various applications, including the automotive and construction sectors. This is particularly critical for electromobility, where lightweight and strong materials are essential.

- Meeting the demand for sustainable materials: The growing demand for sustainable materials across various industries, including automotive, construction, and packaging, is driving the need for low-carbon steel production methods. Eramet's eraLow process directly responds to this market demand.

Eramet's Commitment to Sustainable Steel Production

Eramet's commitment to sustainable steel production extends far beyond the eraLow process. It's deeply embedded within their overall ESG strategy and reflects a broader corporate social responsibility approach.

- Detailed ESG reporting and transparency: Eramet demonstrates a commitment to transparency by publishing detailed ESG reports, showcasing their progress and highlighting their sustainability initiatives. This commitment to transparency builds trust with stakeholders and investors.

- Investment in renewable energy sources: Eramet is actively investing in renewable energy sources to power their operations, including the eraLow process, further reducing their carbon footprint and promoting a transition to a low-carbon economy.

- Commitment to responsible sourcing: Eramet prioritizes responsible sourcing of raw materials, ensuring ethical and sustainable practices throughout their supply chain. This commitment extends to minimizing waste and maximizing resource utilization.

- Focus on circular economy principles: Eramet actively embraces the principles of the circular economy, striving to minimize waste, reuse materials, and maximize resource efficiency across all their operations.

- Partnerships and collaborations: Eramet actively seeks partnerships and collaborations to accelerate the transition to sustainable steel production, fostering innovation and knowledge sharing within the industry.

The Market Impact of eraLow and Future Prospects

The market demand for low-carbon steel is rapidly increasing due to stringent environmental regulations and growing consumer awareness. Eramet's eraLow process positions them strongly within this burgeoning green steel market.

- Growing demand for green steel: Stringent environmental regulations and growing consumer pressure are driving the market demand for sustainable steel products, creating a significant opportunity for companies like Eramet.

- eraLow's competitive advantage: The eraLow process provides Eramet with a significant competitive advantage in the sustainable steel market, allowing them to offer a product with a substantially lower carbon footprint.

- Potential for future improvements: Eramet continues to invest in research and development to further improve the efficiency and sustainability of the eraLow process, maximizing its impact on steel decarbonization.

- Opportunities for partnerships and scaling up: The scalability of the eraLow process presents significant opportunities for partnerships and collaborations, allowing for broader adoption within the steel industry and a more widespread impact on carbon emissions reduction.

- Contribution to a wider shift: The success of eraLow could act as a catalyst for wider change, encouraging other companies within the steel industry to adopt sustainable practices and technologies.

Conclusion

Eramet's eraLow process represents a significant leap forward in steel industry decarbonization. By providing a sustainable method for manganese production, a crucial element in steelmaking, Eramet is paving the way for a greener future in the steel sector. Its commitment to ESG principles and innovation positions them as a key player in the transition to a low-carbon economy. Learn more about Eramet's commitment to sustainable steel production and the innovative eraLow process. Explore how Eramet's eraLow can contribute to your company's sustainability goals. Visit [link to Eramet's website] to discover more about green steel and low-carbon solutions.

Featured Posts

-

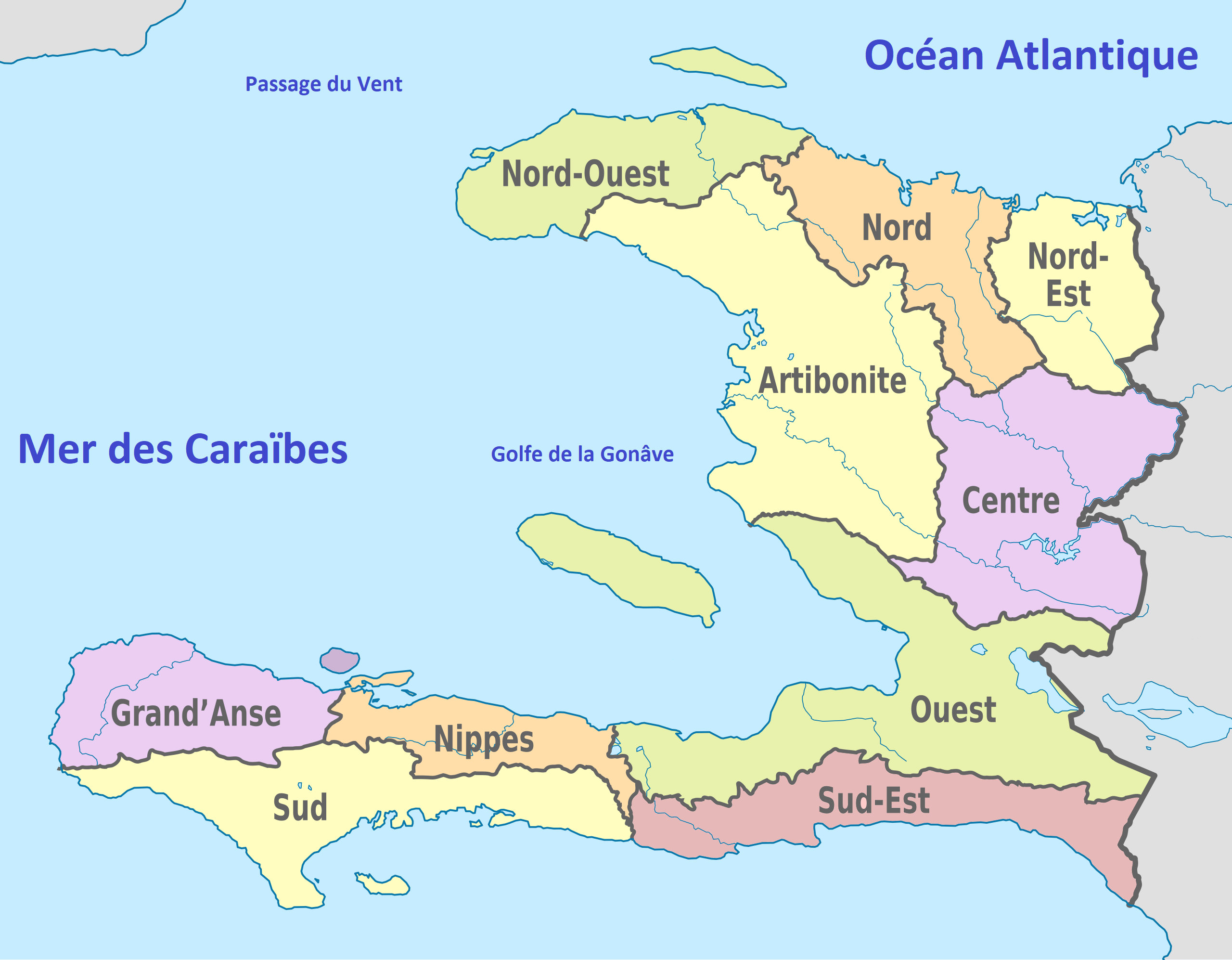

Urgence Humanitaire En Haiti Les Enfants De Moins De 5 Ans Victimes Principales Des Deplacements

May 14, 2025

Urgence Humanitaire En Haiti Les Enfants De Moins De 5 Ans Victimes Principales Des Deplacements

May 14, 2025 -

Wwe Vault Wrestle Mania Iii Livestream Details For Sunday

May 14, 2025

Wwe Vault Wrestle Mania Iii Livestream Details For Sunday

May 14, 2025 -

Eurovision Legend Anne Marie Davids Israel Performance And 2025 Entry Endorsement

May 14, 2025

Eurovision Legend Anne Marie Davids Israel Performance And 2025 Entry Endorsement

May 14, 2025 -

Johan Derksen Onthult Donny Huijsen En De Verkeerde Vrienden Van Zijn Zoon Dean

May 14, 2025

Johan Derksen Onthult Donny Huijsen En De Verkeerde Vrienden Van Zijn Zoon Dean

May 14, 2025 -

Important Recall Notice Potentially Lethal Coffee Creamer In Michigan

May 14, 2025

Important Recall Notice Potentially Lethal Coffee Creamer In Michigan

May 14, 2025

Latest Posts

-

France Denonciation Du Genocide A Gaza Et Oqtf Pour Un Ressortissant Algerien

May 14, 2025

France Denonciation Du Genocide A Gaza Et Oqtf Pour Un Ressortissant Algerien

May 14, 2025 -

Info Bfm Lyon Arrestation Apres Tentative D Intrusion A La Synagogue De Caluire Et Cuire

May 14, 2025

Info Bfm Lyon Arrestation Apres Tentative D Intrusion A La Synagogue De Caluire Et Cuire

May 14, 2025 -

Genocide A Gaza Un Algerien Sous Oqtf En France

May 14, 2025

Genocide A Gaza Un Algerien Sous Oqtf En France

May 14, 2025 -

Synagogue De Caluire Et Cuire Une Tentative D Intrusion Dejouee Par La Police

May 14, 2025

Synagogue De Caluire Et Cuire Une Tentative D Intrusion Dejouee Par La Police

May 14, 2025 -

Un Algerien Expulse De France Apres Avoir Denonce Le Genocide A Gaza

May 14, 2025

Un Algerien Expulse De France Apres Avoir Denonce Le Genocide A Gaza

May 14, 2025