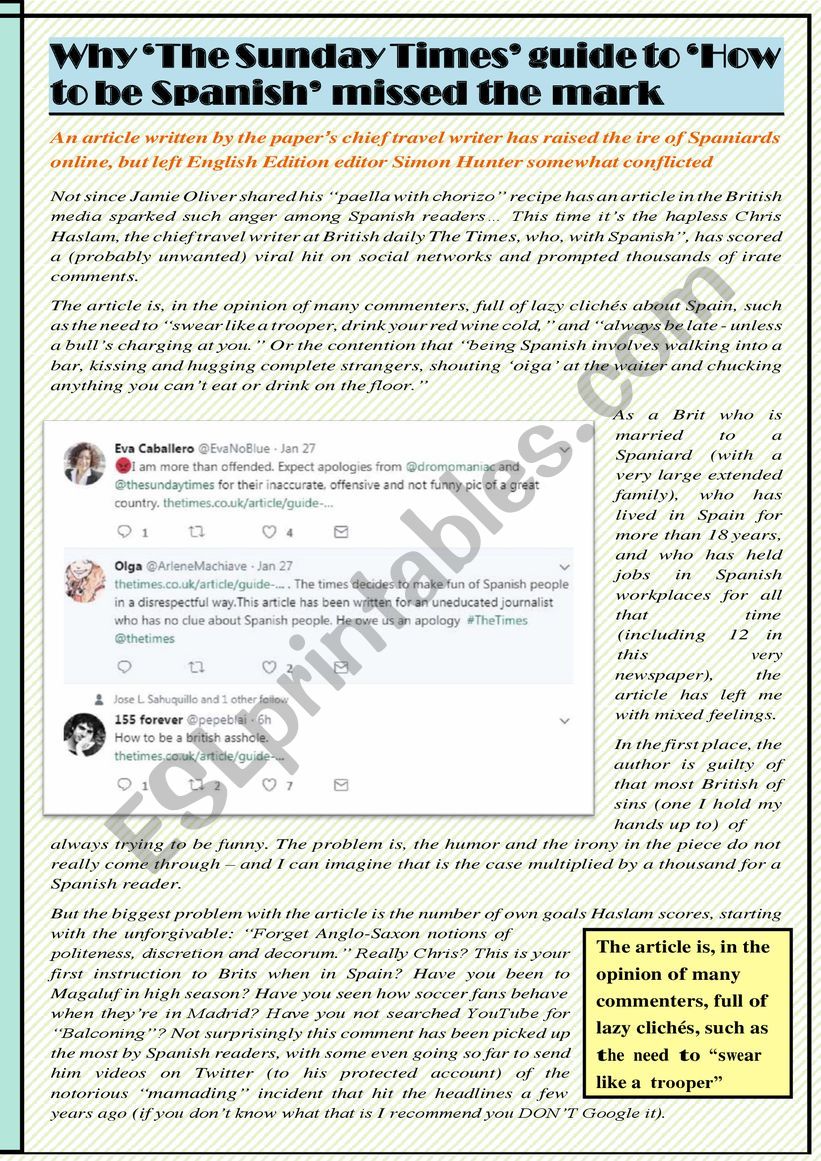

Manufacturing In America: Obstacles And Opportunities

Table of Contents

Obstacles Facing Manufacturing in America

Rising Labor Costs and Skill Gaps

American labor, while often highly skilled, commands higher wages than in many other countries. This cost differential necessitates a strategic focus on automation and a significant investment in upskilling the American workforce. The manufacturing sector faces a critical challenge in attracting and retaining skilled workers in specialized fields, from advanced robotics technicians to precision engineers. This skills gap hinders productivity and competitiveness.

- Difficulty attracting and retaining skilled workers in specialized manufacturing fields. Competition from other industries offering higher salaries or more appealing work environments is fierce.

- The need for increased investment in vocational training and apprenticeships. Bridging the skills gap requires a robust pipeline of trained workers. Investing in vocational schools and apprenticeship programs is crucial. Government partnerships with private sector companies can facilitate this training.

- The impact of automation on employment and the need for reskilling initiatives. While automation increases efficiency, it also displaces some workers. Reskilling programs are essential to help displaced workers transition to new roles within the evolving manufacturing landscape. These programs should focus on the in-demand skills of the future, including data analytics and programming for industrial automation.

Supply Chain Disruptions and Global Competition

The globalized nature of manufacturing exposes American companies to significant vulnerabilities. Geopolitical instability, natural disasters, and unforeseen events like the COVID-19 pandemic have highlighted the risks of relying on complex, globally dispersed supply chains. Furthermore, competition from countries with lower labor costs and less stringent regulations remains intense.

- Vulnerabilities exposed by reliance on global supply chains. The pandemic demonstrated how easily disruptions in one part of the world can cripple entire industries.

- The importance of diversifying supply chains and promoting domestic sourcing. Reducing reliance on single-source suppliers and increasing domestic production enhances resilience. "Nearshoring," moving production to nearby countries, offers a compromise between global sourcing and full reshoring.

- The need for strategic partnerships and collaborations to mitigate risks. Collaboration between manufacturers, suppliers, and government agencies can improve supply chain visibility and responsiveness.

Regulatory Hurdles and Bureaucracy

Navigating the complex web of regulations and bureaucratic processes in the United States can be a significant burden for American manufacturers, impacting efficiency and competitiveness. Excessive red tape increases compliance costs and slows down innovation.

- The streamlining of regulatory processes to reduce compliance costs. Simplifying regulations and reducing unnecessary paperwork can significantly improve efficiency.

- The need for clear and consistent regulations across states. Inconsistent regulations across different states create additional complexities and costs for businesses operating nationally.

- The impact of environmental regulations on manufacturing costs and innovation. While environmental protection is crucial, regulations need to be carefully balanced to avoid stifling innovation and competitiveness. Incentivizing green manufacturing practices can help mitigate this challenge.

Opportunities for Growth in American Manufacturing

Technological Advancements and Automation

Embracing automation and advanced technologies like AI, robotics, and 3D printing is vital for enhancing productivity, improving efficiency, and creating new, high-skill job opportunities in American manufacturing.

- Investment in research and development of advanced manufacturing technologies. Government funding and private sector investment are crucial for driving innovation in this area.

- The integration of Industry 4.0 principles to optimize production processes. Smart factories utilize data analytics and connected systems to improve efficiency and reduce waste.

- The potential for creating high-skilled jobs in technology-driven manufacturing. The shift towards automation creates a demand for skilled technicians, engineers, and data scientists.

Reshoring and Nearshoring Initiatives

Bringing manufacturing jobs back to the U.S. (reshoring) or relocating them to nearby countries (nearshoring) can significantly enhance supply chain resilience, create jobs, and boost local economies.

- Government incentives and policies to encourage reshoring and nearshoring. Tax breaks, grants, and other incentives can make domestic manufacturing more attractive.

- The advantages of reduced transportation costs and lead times. Shorter supply chains lead to faster delivery times and reduced transportation costs.

- The opportunities to support local communities and economies. Reshoring and nearshoring create jobs and stimulate economic growth in local communities.

Focus on Sustainability and Green Manufacturing

Consumers are increasingly demanding sustainable and environmentally friendly products. Adopting green manufacturing practices not only reduces environmental impact but also enhances brand reputation and attracts environmentally conscious consumers.

- The integration of sustainable practices throughout the manufacturing process. This includes using eco-friendly materials, reducing waste, and minimizing energy consumption.

- Investment in renewable energy and energy-efficient technologies. Reducing reliance on fossil fuels lowers operating costs and reduces carbon emissions.

- The development of eco-friendly materials and processes. Innovation in materials science is crucial for creating more sustainable manufacturing processes.

Conclusion

The future of manufacturing in America hinges on addressing the obstacles and capitalizing on the opportunities presented. By investing in workforce development, streamlining regulations, embracing technological advancements, and prioritizing sustainability, the U.S. can strengthen its manufacturing base and regain its global competitiveness. The revitalization of American manufacturing requires a collaborative effort between government, industry, and educational institutions. Let's work together to unlock the full potential of American manufacturing and build a stronger, more resilient economy. Invest in the future of American manufacturing today.

Featured Posts

-

The January 29th Dc Air Disaster What The Ny Times Missed And Why

Apr 29, 2025

The January 29th Dc Air Disaster What The Ny Times Missed And Why

Apr 29, 2025 -

Nyt Strands Game 422 Hints And Answers For April 29th Tuesday

Apr 29, 2025

Nyt Strands Game 422 Hints And Answers For April 29th Tuesday

Apr 29, 2025 -

Strong Earnings Boost Reliance Share Price To 10 Month Peak

Apr 29, 2025

Strong Earnings Boost Reliance Share Price To 10 Month Peak

Apr 29, 2025 -

Du Val Founder Kenyon Clarke Detained After Auckland Altercation

Apr 29, 2025

Du Val Founder Kenyon Clarke Detained After Auckland Altercation

Apr 29, 2025 -

Becciu Trial Fresh Evidence Casts Doubt On Verdict

Apr 29, 2025

Becciu Trial Fresh Evidence Casts Doubt On Verdict

Apr 29, 2025

Latest Posts

-

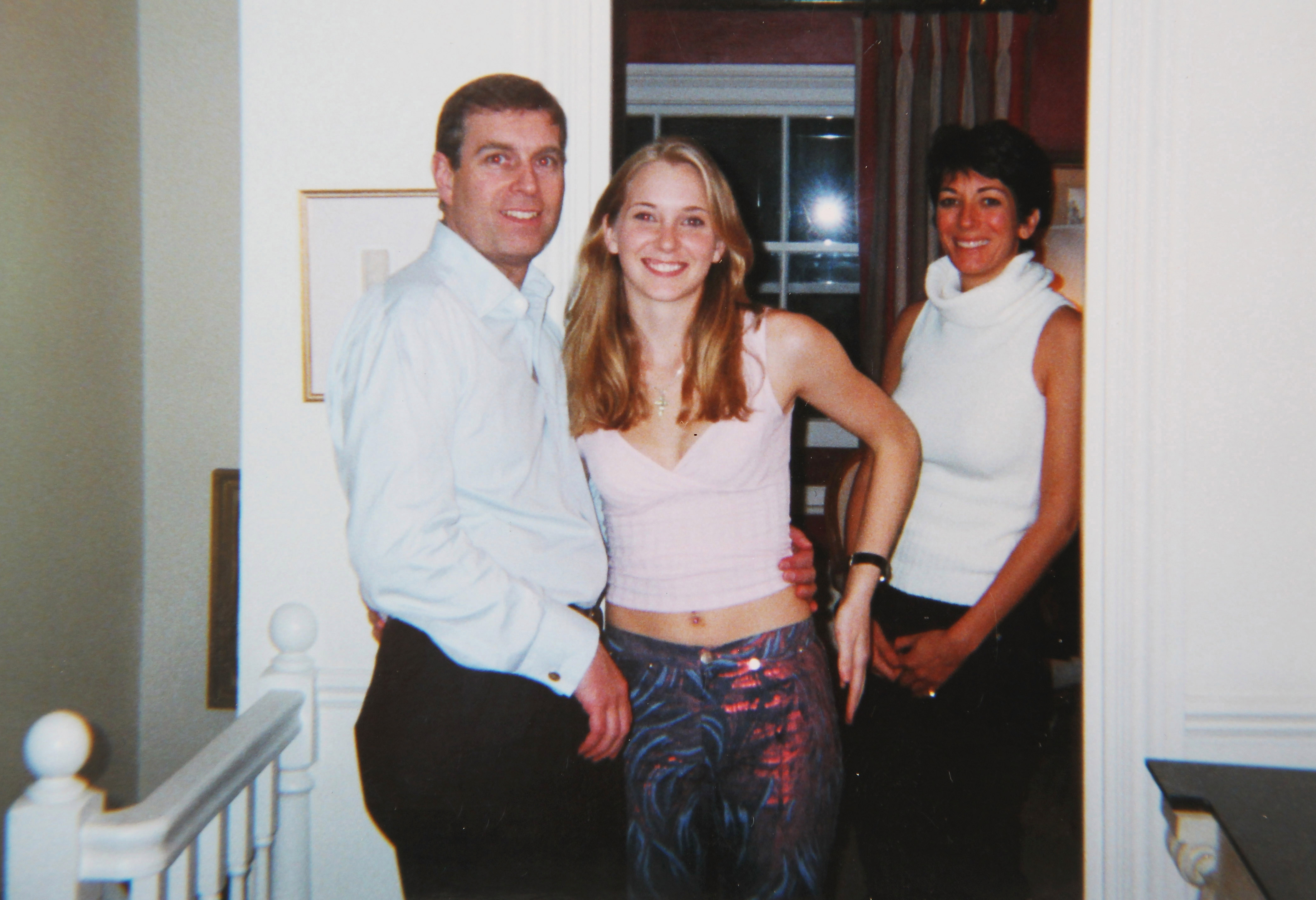

Prince Andrews Temperament Explosive Revelations From Palace Staff

May 12, 2025

Prince Andrews Temperament Explosive Revelations From Palace Staff

May 12, 2025 -

Prince Andrew Facing New Allegations Undercover Video Reveals Potential Underage Relationship

May 12, 2025

Prince Andrew Facing New Allegations Undercover Video Reveals Potential Underage Relationship

May 12, 2025 -

Skandal Masazystka Odkrywa Prawde O Ksieciu Andrzeju

May 12, 2025

Skandal Masazystka Odkrywa Prawde O Ksieciu Andrzeju

May 12, 2025 -

Virginia Giuffre Skandalen En Analyse Av Hendelsene Og Reaksjonene

May 12, 2025

Virginia Giuffre Skandalen En Analyse Av Hendelsene Og Reaksjonene

May 12, 2025 -

Virginia Giuffres Shocking Claim Only Four Days To Live

May 12, 2025

Virginia Giuffres Shocking Claim Only Four Days To Live

May 12, 2025