Overcoming Hurdles In Automated Visual Inspection Of Lyophilized Drug Products

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Drug Products

The inherent complexities of lyophilized drug products pose significant challenges for automated visual inspection systems. These challenges require innovative solutions to ensure accurate and reliable defect detection.

Variability in Lyophilized Product Appearance

Lyophilized cakes exhibit natural variations in appearance, making automated defect detection difficult. These variations, including cracks, fissures, and subtle color differences, can be challenging to distinguish from actual defects. This can lead to a high rate of false positives, potentially resulting in the rejection of perfectly acceptable vials.

- Examples of acceptable vs. unacceptable variations: A small, hairline crack might be acceptable, whereas a large crack compromising the cake integrity would be unacceptable. Similarly, minor color variations within an acceptable range are permissible, while significant discoloration could indicate a problem.

- Impact of formulation changes on visual appearance: Changes in formulation can significantly alter the visual characteristics of the lyophilized cake, necessitating adjustments to the automated inspection system's parameters.

- Challenges in defining clear acceptance criteria: Establishing clear and unambiguous acceptance criteria that account for natural variations while still identifying critical defects remains a significant challenge. This requires a thorough understanding of the product's characteristics and careful consideration of regulatory guidelines.

Lighting and Image Acquisition Challenges

The surface texture of lyophilized cakes and the potential for light reflection create significant challenges for image acquisition. Obtaining consistent and high-quality images is crucial for accurate defect detection. Variations in lighting can lead to shadows and glare, obscuring defects or creating false positives.

- Impact of lighting on defect detection: Incorrect lighting can mask subtle defects or create artifacts that are misinterpreted as defects. The use of appropriate lighting techniques is therefore crucial.

- Challenges with different vial types and sizes: Variations in vial types and sizes can affect the uniformity of illumination and the overall image quality. Automated systems need to adapt to these differences.

- Importance of image resolution and clarity: High-resolution images are essential for detecting small defects and subtle variations in the lyophilized cake. Image clarity is vital to avoid misinterpretations.

Software and Algorithm Limitations

Current image analysis algorithms may struggle to accurately identify defects in lyophilized products due to the inherent variability in appearance and the complexity of distinguishing between acceptable variations and actual defects. This necessitates the development of more advanced algorithms.

- Challenges in distinguishing between defects and acceptable variations: The subtle nature of some defects and the natural variations in lyophilized cake appearance make it difficult for algorithms to reliably distinguish between them.

- Need for machine learning and AI in improving accuracy: Machine learning (ML) and artificial intelligence (AI) offer significant potential for improving the accuracy and efficiency of automated visual inspection. AI algorithms can learn from large datasets of images, improving their ability to identify defects and minimize false positives.

- Importance of robust training data sets: The accuracy of AI-powered algorithms depends heavily on the quality and quantity of the training data. A robust and representative dataset is crucial for achieving optimal performance.

Strategies for Overcoming These Challenges

Addressing the challenges in automated visual inspection requires a multi-faceted approach, combining advanced technologies and innovative strategies.

Advanced Image Processing Techniques

Sophisticated image processing techniques can significantly enhance the accuracy of defect detection. These techniques can improve image quality, highlight subtle defects, and reduce the impact of lighting variations.

- Specific examples of image processing algorithms: Techniques like image enhancement (contrast stretching, sharpening), filtering (noise reduction, edge detection), and segmentation can be applied to improve defect detection.

- Benefits and limitations of each technique: Each technique has its own benefits and limitations, and the optimal approach often involves a combination of techniques tailored to the specific product and system.

- Integration with automated visual inspection systems: Successful implementation requires seamless integration of these techniques into the automated visual inspection system's software.

Improved Lighting and Imaging Systems

Investing in specialized lighting systems and high-resolution cameras is essential for obtaining high-quality images. Optimized lighting minimizes shadows and glare, enhancing the visibility of defects.

- Different types of lighting systems and their applications: Diffuse lighting, directional lighting, and structured lighting are examples of techniques used to optimize image quality.

- Advantages of high-resolution cameras: High-resolution cameras capture finer details, improving the detection of small defects.

- Importance of system calibration and validation: Regular calibration and validation of the lighting and imaging systems are vital for maintaining consistent performance and accuracy.

Development of Robust AI-powered Algorithms

AI and machine learning offer transformative potential for improving the accuracy and efficiency of automated visual inspection. AI algorithms can learn to recognize defects and differentiate them from acceptable variations, significantly reducing false positives.

- Types of machine learning algorithms suitable for this application: Convolutional neural networks (CNNs) and other deep learning algorithms are particularly well-suited for image analysis tasks.

- Importance of data quality and quantity for training AI models: Large, high-quality datasets are crucial for training accurate and reliable AI models. Data augmentation techniques can be used to expand limited datasets.

- Benefits of using AI for continuous improvement and adaptation: AI systems can continuously learn and adapt as new data becomes available, improving their performance over time.

Conclusion: Optimizing Automated Visual Inspection of Lyophilized Drug Products

Efficient and accurate Automated Visual Inspection of Lyophilized Drug Products is crucial for maintaining product quality and patient safety. Overcoming the challenges requires a holistic approach encompassing advanced image processing, improved lighting and imaging systems, and the development of robust AI-powered algorithms. By implementing these strategies, pharmaceutical manufacturers can significantly improve the accuracy and efficiency of their visual inspection processes, ensuring that only high-quality lyophilized drug products reach the market. Contact us to learn more about optimizing your Automated Visual Inspection of Lyophilized Drug Products and ensuring the highest standards of quality control.

Featured Posts

-

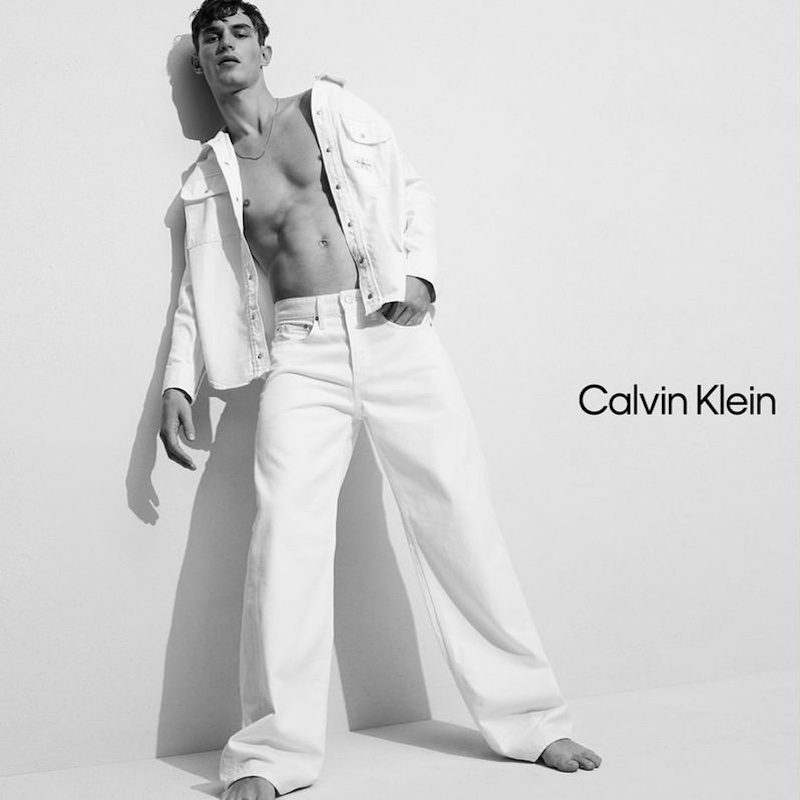

Lily Collins Stars In A New Calvin Klein Campaign Images And Details

May 12, 2025

Lily Collins Stars In A New Calvin Klein Campaign Images And Details

May 12, 2025 -

Continued Stricter Border Checks In The Netherlands A Trend Analysis

May 12, 2025

Continued Stricter Border Checks In The Netherlands A Trend Analysis

May 12, 2025 -

Hanouna Sur M6 Un Animateur Vedette Reagit A L Arrivee Du Trublion

May 12, 2025

Hanouna Sur M6 Un Animateur Vedette Reagit A L Arrivee Du Trublion

May 12, 2025 -

Selena Gomezs 3 000 Benny Blanco Diamond Ring A 12 Sale

May 12, 2025

Selena Gomezs 3 000 Benny Blanco Diamond Ring A 12 Sale

May 12, 2025 -

Where To Watch Celtics Vs Knicks Live Stream Tv Channel And Game Details

May 12, 2025

Where To Watch Celtics Vs Knicks Live Stream Tv Channel And Game Details

May 12, 2025

Latest Posts

-

The Most Emotional Rocky Movie According To Sylvester Stallone

May 12, 2025

The Most Emotional Rocky Movie According To Sylvester Stallone

May 12, 2025 -

Which Rocky Movie Touches Sylvester Stallone The Most

May 12, 2025

Which Rocky Movie Touches Sylvester Stallone The Most

May 12, 2025 -

Stallone Reveals His Top Rocky Movie A Touching Choice

May 12, 2025

Stallone Reveals His Top Rocky Movie A Touching Choice

May 12, 2025 -

Sylvester Stallone Picks His Most Emotional Rocky Film

May 12, 2025

Sylvester Stallone Picks His Most Emotional Rocky Film

May 12, 2025 -

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025

Sylvester Stallones Favorite Rocky Movie The Franchises Most Emotional Entry

May 12, 2025