The Complexities Of All-American Product Manufacturing

Table of Contents

The High Cost of Domestic Manufacturing

One of the most significant obstacles to All-American product manufacturing is the undeniably higher cost of production compared to many overseas competitors. This cost differential stems primarily from labor expenses and raw material sourcing challenges.

Labor Costs

US labor wages significantly exceed those in many other countries, directly impacting production costs. This disparity is particularly pronounced in labor-intensive industries.

- Higher labor costs in specific industries: Textile manufacturing, electronics assembly, and garment production consistently demonstrate higher labor costs in the US compared to countries like China, Vietnam, and Bangladesh.

- Impact of minimum wage laws and unionization: Minimum wage laws and the prevalence of unionized labor in certain sectors further contribute to increased labor costs in the US. These factors, while crucial for worker welfare, must be factored into production cost analyses.

Raw Material Sourcing

Sourcing raw materials domestically presents another significant challenge. Many specialized components or raw materials may not be readily available within the US, necessitating imports and adding to the overall cost.

- Industries reliant on imported raw materials: The automotive industry, for example, relies heavily on imported rare earth minerals and specialized components. Similarly, many electronics manufacturers depend on imported semiconductors and other specialized materials.

- Environmental impact and transportation costs: Domestically sourcing raw materials often involves longer transportation distances, increasing fuel costs and potentially raising the environmental impact of production. This necessitates careful consideration of sustainable sourcing practices.

Navigating Regulatory Compliance

The US boasts a robust regulatory framework designed to protect workers, consumers, and the environment. However, complying with these regulations significantly impacts the cost and complexity of All-American product manufacturing.

Environmental Regulations

Stringent environmental regulations, implemented by agencies like the Environmental Protection Agency (EPA), mandate compliance with emission standards, waste disposal protocols, and other environmental safeguards.

- Examples of relevant environmental regulations: The Clean Air Act, Clean Water Act, and Resource Conservation and Recovery Act are crucial regulations impacting manufacturing processes.

- Costs associated with environmental compliance and certifications: Meeting these standards often involves substantial investments in pollution control equipment, waste management systems, and environmental audits, increasing overall production costs.

Labor and Safety Regulations

The Occupational Safety and Health Administration (OSHA) sets comprehensive standards for workplace safety. Compliance necessitates investment in safety equipment, worker training programs, and adherence to strict operational protocols.

- OSHA regulations and their impact on manufacturing processes: OSHA mandates directly influence manufacturing processes, requiring modifications to equipment, workflows, and training procedures to ensure worker safety.

- Costs associated with worker training and safety equipment: Providing comprehensive safety training, purchasing safety equipment, and implementing safety protocols represent significant upfront and ongoing costs for manufacturers.

Competition and Market Dynamics

All-American product manufacturing faces intense competition, both domestically and globally. This competition significantly influences pricing strategies, market share, and the overall viability of domestic production.

Global Competition

Lower production costs in many other countries create a challenging competitive landscape. Imports often undercut domestically produced goods, particularly in price-sensitive markets.

- Industries heavily impacted by foreign competition: The apparel, footwear, and furniture industries are particularly vulnerable to competition from countries with lower labor and production costs.

- Strategies for competing in a global market: Strategies to counter this competition include focusing on quality, innovation, specialized niche markets, and leveraging the "Made in America" brand appeal.

Consumer Demand and Pricing

Consumer preferences play a crucial role. While there is a growing appreciation for domestically made goods, consumers are also highly price-sensitive. The higher production costs of All-American products often translate into higher retail prices.

- Marketing strategies to highlight the value proposition: Marketing campaigns that emphasize quality, durability, ethical sourcing, and the support of American jobs are crucial to justify higher prices.

- Potential for niche markets and premium pricing: Focusing on niche markets with a strong appreciation for domestically produced goods can enable premium pricing strategies.

Technological Advancements and Automation

Technological advancements and automation offer potential solutions to mitigate some of the challenges associated with higher labor costs and increased competition.

Automation as a Solution

Automation technologies can reduce reliance on manual labor, enhancing efficiency and lowering production costs in the long run.

- Examples of automation technologies: Robotics, computer-aided manufacturing (CAM), and advanced automation systems are increasingly employed in All-American manufacturing.

- Initial investment costs and long-term benefits: While the initial investment in automation can be substantial, the long-term benefits often include increased productivity, improved quality control, and reduced labor costs.

Reshoring and Technological Innovation

Technological innovation is a key driver of reshoring – the return of manufacturing jobs to the US. Advancements in automation and digital manufacturing make domestic production more competitive.

- Examples of technological advancements driving reshoring: Additive manufacturing (3D printing), advanced robotics, and improved supply chain management technologies are all contributing to reshoring initiatives.

- Potential for technological innovation to improve efficiency and competitiveness: Continuous investment in research and development and the adoption of cutting-edge technologies are crucial for enhancing the competitiveness of All-American product manufacturing.

Conclusion

All-American product manufacturing presents a compelling vision, but realizing it requires navigating a complex interplay of high costs, stringent regulations, and intense global competition. While the challenges are significant, the opportunities are equally substantial. By strategically leveraging automation, focusing on niche markets, and emphasizing the value proposition of domestically produced goods, businesses can successfully navigate these complexities. Technological advancements offer a crucial pathway towards enhancing efficiency and competitiveness. Learn more about the intricacies of All-American product manufacturing and discover how you can contribute to this vital sector of the US economy.

Featured Posts

-

Porsche Macan Fyrsta 100 Rafutgafan Kynnt

Apr 29, 2025

Porsche Macan Fyrsta 100 Rafutgafan Kynnt

Apr 29, 2025 -

11 Minciu Apie M Ivaskeviciaus Isvaryma Filmas Priesistore Keiksmai Ir Daugiau

Apr 29, 2025

11 Minciu Apie M Ivaskeviciaus Isvaryma Filmas Priesistore Keiksmai Ir Daugiau

Apr 29, 2025 -

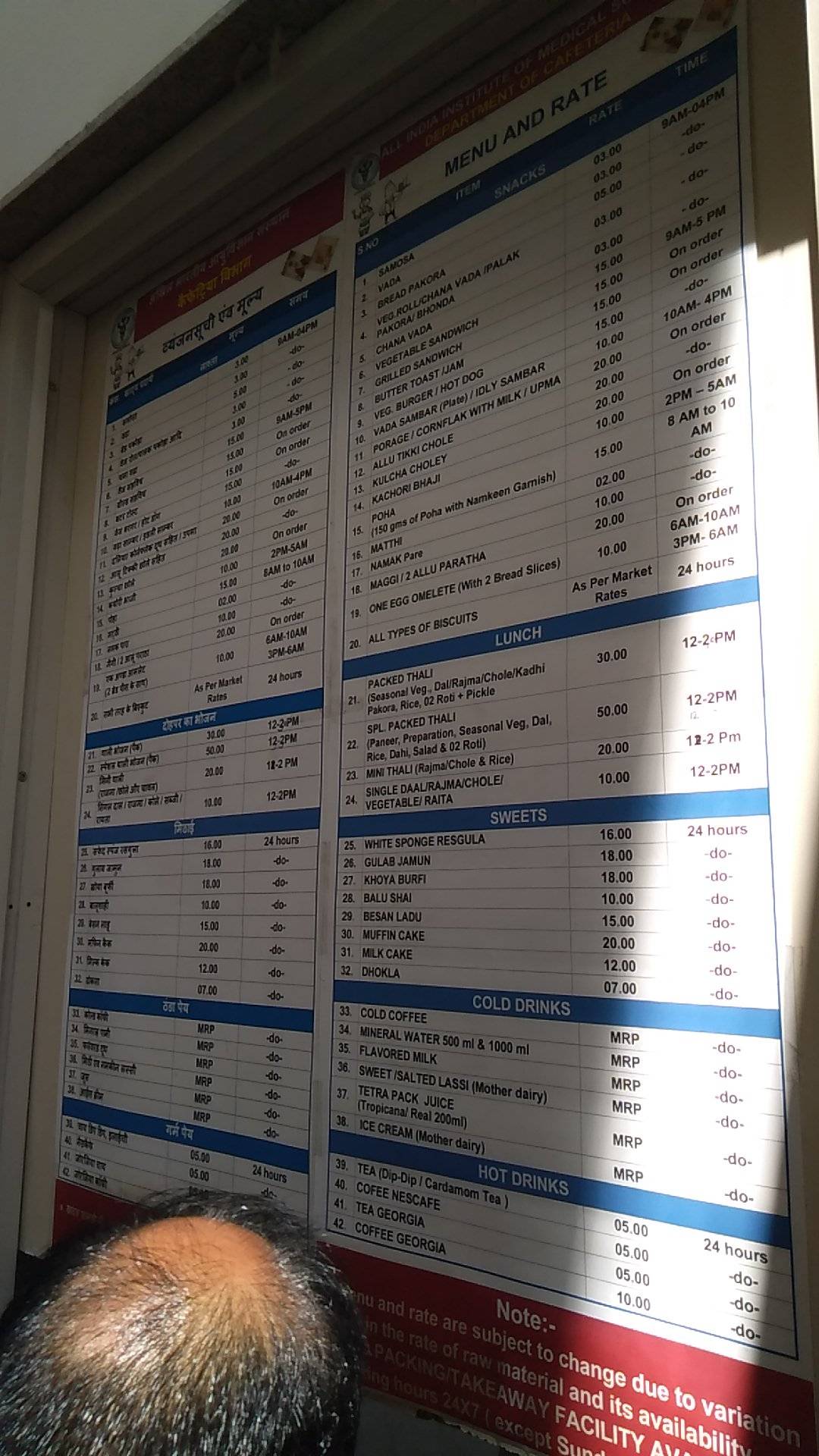

Adhd Diagnosis On The Rise At Aiims Opd Factors Contributing To The Increase In Young Adults

Apr 29, 2025

Adhd Diagnosis On The Rise At Aiims Opd Factors Contributing To The Increase In Young Adults

Apr 29, 2025 -

Will Trump Pardon Pete Rose Examining The Case And Its Implications

Apr 29, 2025

Will Trump Pardon Pete Rose Examining The Case And Its Implications

Apr 29, 2025 -

Cassidy Hutchinsons Fall Book Release Insights Into The January 6th Hearings

Apr 29, 2025

Cassidy Hutchinsons Fall Book Release Insights Into The January 6th Hearings

Apr 29, 2025

Latest Posts

-

B And W Trailer Hitches Heavy Hitters All Star Event 100 K Bass Fishing Tournament At Smith Mountain Lake

May 12, 2025

B And W Trailer Hitches Heavy Hitters All Star Event 100 K Bass Fishing Tournament At Smith Mountain Lake

May 12, 2025 -

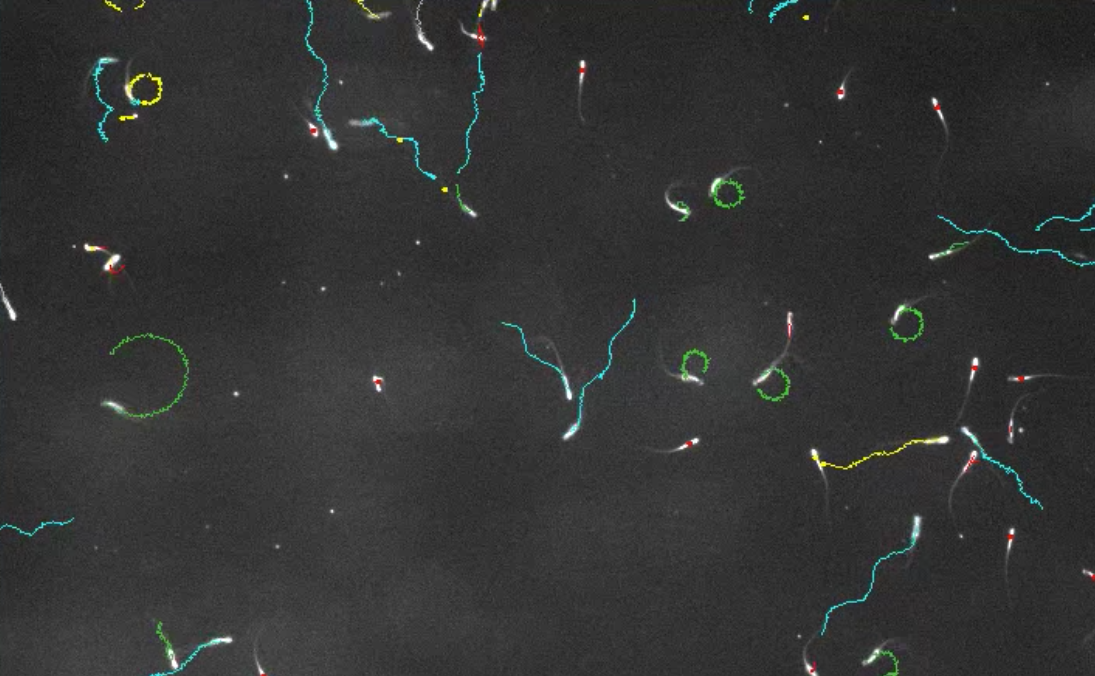

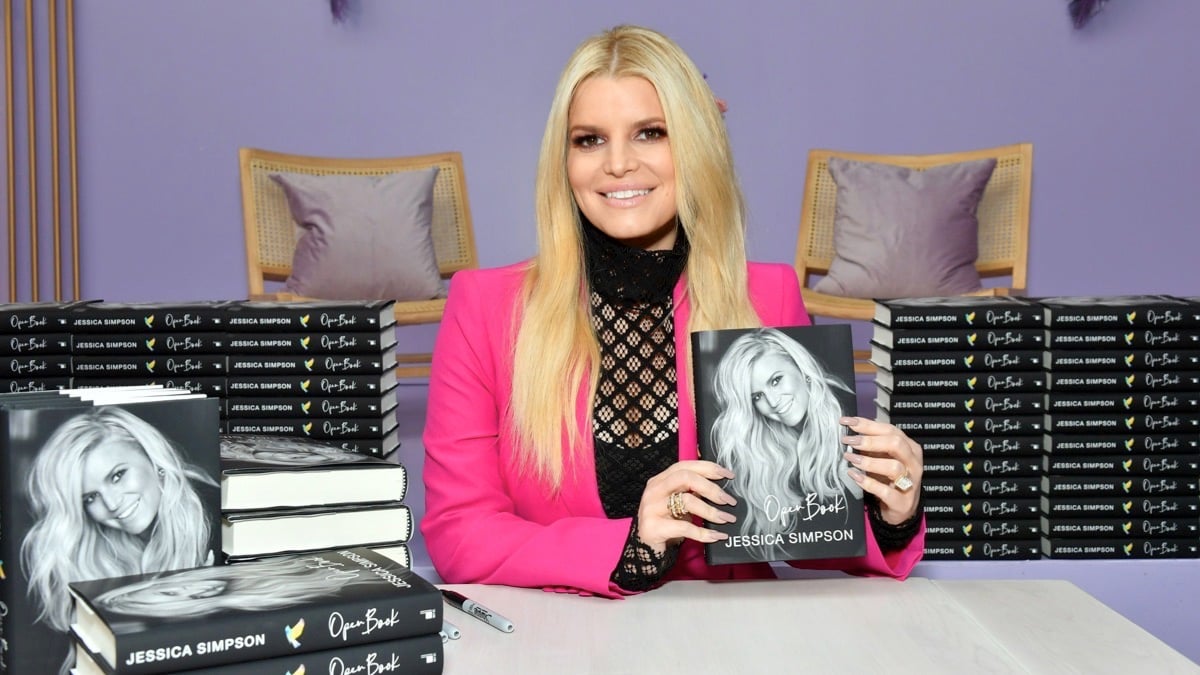

Exploring The Source Of The Jessica Simpson Snake Sperm Rumor

May 12, 2025

Exploring The Source Of The Jessica Simpson Snake Sperm Rumor

May 12, 2025 -

Fact Checking Jessica Simpsons Statement On Snake Sperm

May 12, 2025

Fact Checking Jessica Simpsons Statement On Snake Sperm

May 12, 2025 -

The Context And Impact Of Jessica Simpsons Snake Sperm Claim

May 12, 2025

The Context And Impact Of Jessica Simpsons Snake Sperm Claim

May 12, 2025 -

Analysis Of Jessica Simpsons Alleged Snake Sperm Endorsement

May 12, 2025

Analysis Of Jessica Simpsons Alleged Snake Sperm Endorsement

May 12, 2025