The Complexities Of Automated Nike Sneaker Assembly

Table of Contents

The Role of Robotics in Modern Sneaker Manufacturing

The integration of robotics in Nike's sneaker manufacturing represents a significant leap forward in efficiency and precision. Automated systems are revolutionizing various stages of the production process, leading to higher output and improved quality control. Keywords: Nike Robotics, Shoe Assembly Robots, Automated Shoe Assembly Line, Industrial Robots in Footwear.

-

Precise Stitching and Assembly: Robotic arms, equipped with advanced sensors and programming, perform intricate stitching tasks with unmatched accuracy and speed. This minimizes errors and ensures consistent quality across all pairs of shoes. These robots are programmed to handle the specific nuances of different Nike sneaker models, adapting to various material types and designs.

-

Automated Glue Dispensing: Robotic systems precisely dispense adhesives, optimizing glue application for strength and durability while minimizing waste. This automated process contributes to a faster assembly time and reduces material costs.

-

Robotic Quality Control: Advanced vision systems and robotic arms are used to inspect finished sneakers, identifying defects and ensuring that each pair meets the rigorous quality standards set by Nike. This automated quality control is crucial for maintaining the brand's reputation for excellence.

-

Examples of Nike Automation: While Nike doesn't publicly disclose the specifics of all its automated production lines, various reports and industry analyses suggest a significant deployment of robotics across numerous factories globally. The focus is on incorporating robotics strategically where they provide the greatest efficiency gains and quality improvements.

-

Quantifying Automation: While precise figures on the percentage of automation in Nike's production process are proprietary information, it's evident that automation is playing an increasingly significant role, contributing substantially to the overall efficiency of sneaker production.

Challenges and Limitations of Automated Sneaker Assembly

Despite the advantages, the implementation of automated sneaker assembly presents considerable challenges. Keywords: Automation Challenges Nike, Sneaker Manufacturing Bottlenecks, Limitations of Robotic Shoe Production, Cost of Sneaker Automation.

-

High Initial Investment: The cost of purchasing, installing, and integrating advanced robotic systems represents a substantial initial investment. This financial hurdle can be a barrier for smaller manufacturers and even presents a strategic challenge for large corporations like Nike.

-

Specialized Maintenance and Repair: Maintaining and repairing complex robotic systems requires highly skilled technicians. The need for specialized expertise adds to the overall operational costs and can present a bottleneck in production if timely repairs aren't readily available.

-

Integration Challenges: Integrating robotic systems into existing production lines can be complex and disruptive. Existing workflows and infrastructure may need significant modifications to accommodate the new automation, leading to downtime and additional costs.

-

Job Displacement and Retraining: The increased use of automation in sneaker manufacturing naturally raises concerns about job displacement. Addressing this requires proactive measures, such as retraining programs to equip workers with the skills needed for new roles in the evolving manufacturing landscape.

-

Dexterity and Adaptability Limits: Certain aspects of sneaker assembly still require the dexterity and adaptability of human workers. Tasks involving complex material handling or dealing with unexpected variations in materials remain difficult to fully automate.

The Future of Automated Nike Sneaker Assembly: Innovation and Sustainability

The future of automated Nike sneaker assembly is bright, driven by continuous innovation and a growing focus on sustainability. Keywords: Future of Nike Automation, Sustainable Sneaker Production, AI in Shoe Manufacturing, Smart Factories Nike.

-

AI and Machine Learning Optimization: The integration of AI and machine learning holds the potential to further optimize the automated assembly process. AI algorithms can analyze vast amounts of data to predict potential problems, improve efficiency, and enhance quality control.

-

Advanced Materials and 3D Printing: The use of advanced materials and 3D printing technologies promises to revolutionize sneaker manufacturing. 3D printing can lead to customized production and reduced waste, contributing to a more sustainable manufacturing process.

-

Sustainable Production Methods: Automation plays a vital role in achieving more sustainable production methods. Robotics can improve energy efficiency, minimize waste, and reduce the environmental impact of sneaker manufacturing.

-

Personalized Sneaker Production: Automated systems pave the way for personalized sneaker production. Customized shoes designed and manufactured to individual preferences are becoming increasingly feasible, offering new opportunities for consumers and brands alike.

-

Emerging Trends: The footwear industry is witnessing rapid advancements in robotic automation, including collaborative robots (cobots) designed to work safely alongside human workers and the use of advanced sensor technologies for improved quality control and process monitoring.

Conclusion

The automated assembly of Nike sneakers represents a complex interplay of technological progress, economic realities, and social considerations. While automation offers substantial advantages in efficiency and precision, challenges regarding cost, maintenance, and workforce adaptation require careful consideration. The future of this process hinges on continuous innovation in robotics, AI, and sustainable manufacturing practices. To stay at the forefront of this dynamic field, understanding the intricacies of automated Nike sneaker assembly is critical. Continue exploring resources on advanced manufacturing and robotic automation to remain informed about the latest developments in this exciting area of the footwear industry.

Featured Posts

-

Saudi Aramco Byd Collaboration A New Era In Ev Development

Apr 22, 2025

Saudi Aramco Byd Collaboration A New Era In Ev Development

Apr 22, 2025 -

Higher Stock Prices Higher Risks What Investors Should Know

Apr 22, 2025

Higher Stock Prices Higher Risks What Investors Should Know

Apr 22, 2025 -

Reflecting On The Life And Legacy Of Pope Francis

Apr 22, 2025

Reflecting On The Life And Legacy Of Pope Francis

Apr 22, 2025 -

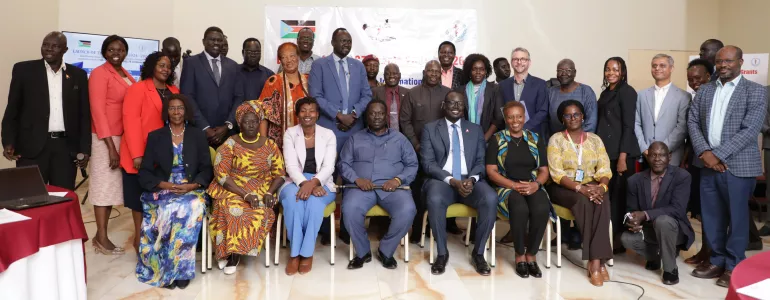

South Sudan Us Partnership Coordinating The Repatriation Of Deportees

Apr 22, 2025

South Sudan Us Partnership Coordinating The Repatriation Of Deportees

Apr 22, 2025 -

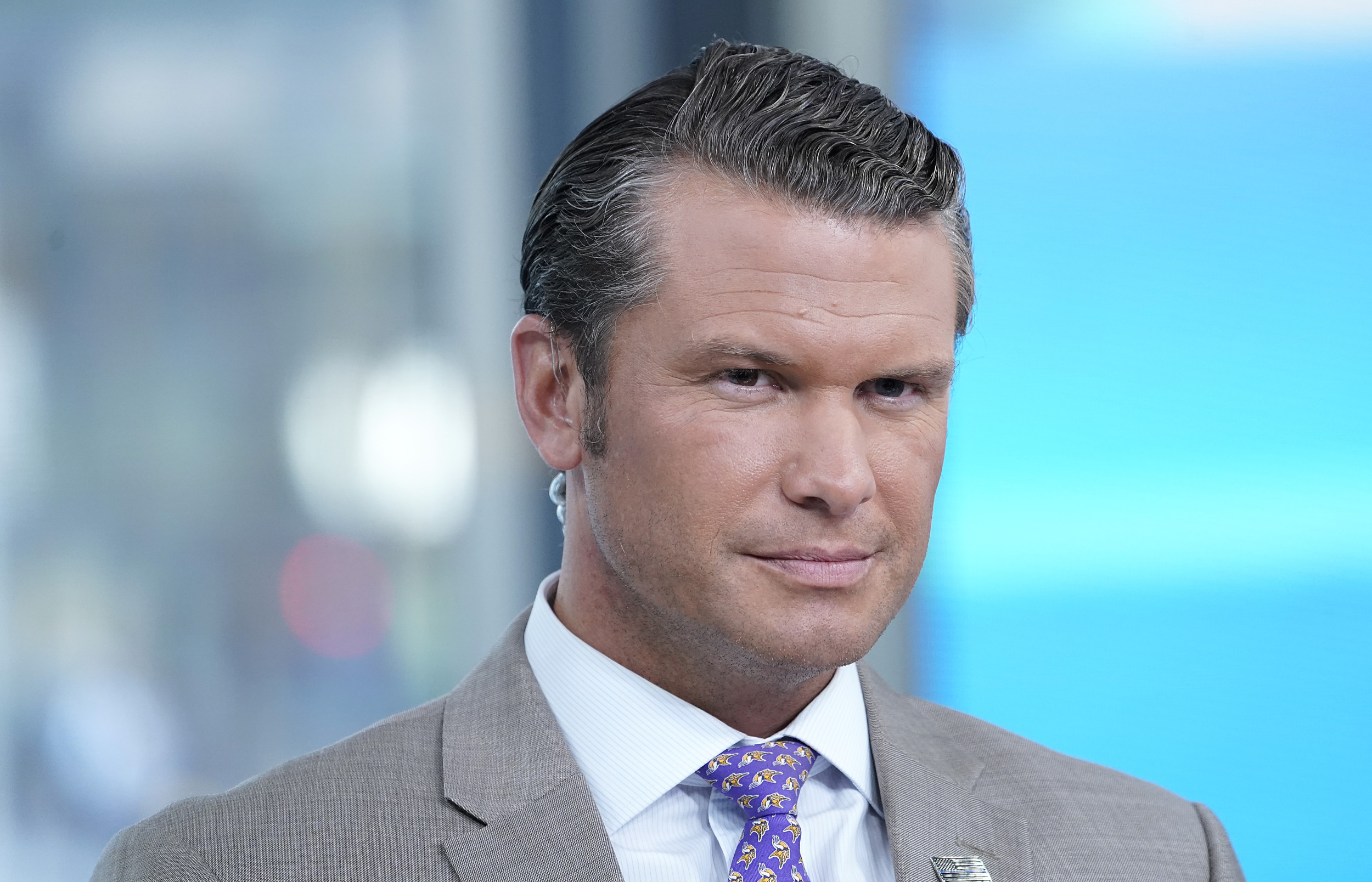

Pentagon Chaos And Signal Chat Controversy Examining The Hegseth Allegations

Apr 22, 2025

Pentagon Chaos And Signal Chat Controversy Examining The Hegseth Allegations

Apr 22, 2025