The Dysprosium Shortage: Implications For The Future Of Electric Vehicles

Table of Contents

Dysprosium's Critical Role in Electric Vehicle Motors

Electric vehicle motors rely heavily on powerful neodymium magnets for their efficient operation. These magnets, while incredibly strong and energy-efficient, contain a crucial component: dysprosium.

Neodymium Magnets and Dysprosium's Importance

Dysprosium significantly enhances the performance of neodymium magnets, particularly their resistance to demagnetization at high temperatures. This temperature stability is critical for electric vehicle motors, which can generate considerable heat during operation. Without sufficient dysprosium, the magnets lose their strength, reducing motor efficiency and potentially leading to motor failure.

- Enhanced Magnetic Strength: Dysprosium boosts the overall magnetic field strength of the neodymium magnets.

- Improved Temperature Stability: It prevents significant loss of magnetic strength at high operating temperatures.

- Increased Durability: Dysprosium contributes to the overall durability and lifespan of the magnets.

A typical electric vehicle motor may contain several kilograms of neodymium magnets, with a significant percentage composed of dysprosium. This makes even a minor dysprosium shortage potentially impactful on EV production.

Alternative Magnet Technologies

The reliance on dysprosium presents a vulnerability. Researchers are actively exploring alternative magnet technologies, but each faces challenges:

- Ferrite Magnets: These are cheaper and more readily available but significantly weaker and less efficient than neodymium magnets. This would necessitate larger and heavier motors, impacting EV performance and range.

- Samarium-Cobalt Magnets: These offer better performance than ferrite magnets but are more expensive and less abundant than neodymium magnets. They also typically don't perform as well as neodymium-dysprosium magnets.

Finding a viable and scalable alternative to neodymium-dysprosium magnets is crucial for mitigating the risks associated with the dysprosium shortage.

The Current Dysprosium Supply Chain and its Vulnerabilities

The global dysprosium supply chain is highly concentrated, creating significant vulnerabilities.

Geographic Concentration of Dysprosium Mining

Dysprosium production is heavily concentrated in a few countries, primarily China. This geographic concentration creates significant geopolitical and economic risks.

- China's Dominance: China currently controls a significant portion of the global dysprosium supply.

- Geopolitical Instability: Any disruption in these regions, whether due to political instability, natural disasters, or trade disputes, can severely impact the global dysprosium supply.

This dependence on a limited number of sources makes the supply chain extremely vulnerable to disruptions.

Mining and Processing Challenges

The mining and processing of dysprosium pose significant environmental and logistical challenges:

- Environmental Impact: Dysprosium mining can have a significant environmental impact, including habitat destruction and water pollution.

- Energy-Intensive Refining: The process of refining dysprosium is energy-intensive, contributing to carbon emissions.

Addressing these challenges requires a concerted effort toward sustainable mining practices and the development of more efficient and environmentally friendly refining technologies.

Implications of the Dysprosium Shortage for the EV Industry

The dysprosium shortage has significant implications for the electric vehicle industry:

Increased EV Production Costs

The limited supply of dysprosium is expected to drive up prices, resulting in increased production costs for EV manufacturers.

- Potential Cost Increases: Estimates suggest a substantial increase in the cost of neodymium magnets due to dysprosium scarcity.

- Impact on EV Prices: These increased costs will likely be passed on to consumers, potentially impacting the affordability and accessibility of EVs.

Potential Slowdown in EV Adoption

Supply chain constraints caused by the dysprosium shortage could lead to a slowdown in the anticipated rate of EV adoption.

- Impact on Government Targets: Governments aiming for ambitious EV adoption targets might find it challenging to meet their goals due to supply limitations.

- Market Disruption: The shortage could lead to market instability, with potential delays in EV production and potential shortages of vehicles.

R&D and Innovation in Magnet Technology

The dysprosium shortage is accelerating research and development efforts focused on alternative magnet materials and improved magnet design.

- Government Funding & Private Investment: Significant investments are being made to explore and develop alternative magnet technologies.

- Promising New Technologies: Several promising technologies are emerging, although their large-scale implementation may take several years.

Conclusion

The dysprosium shortage poses a significant challenge to the future of electric vehicles. The reliance on dysprosium for high-performance EV motors, coupled with the vulnerabilities of the current supply chain, could lead to increased costs, slower adoption rates, and market instability. Understanding the dysprosium shortage is crucial for navigating the future of electric vehicle development. Further research into sustainable mining practices, alternative magnet technologies, and innovative supply chain management strategies is essential to ensure a sustainable and prosperous future for the electric vehicle industry. Let's address the dysprosium shortage and ensure a sustainable future for electric vehicles.

Featured Posts

-

Tragedy Strikes North Carolina University Shooting Leaves Seven Casualties

Apr 29, 2025

Tragedy Strikes North Carolina University Shooting Leaves Seven Casualties

Apr 29, 2025 -

Is The One Plus 13 R Worth It A Comprehensive Review And Analysis

Apr 29, 2025

Is The One Plus 13 R Worth It A Comprehensive Review And Analysis

Apr 29, 2025 -

Videos Show Raid Of Underground Nightclub Over 100 Immigrants Detained

Apr 29, 2025

Videos Show Raid Of Underground Nightclub Over 100 Immigrants Detained

Apr 29, 2025 -

Culture Departments Annual Canoe Awakening Celebration

Apr 29, 2025

Culture Departments Annual Canoe Awakening Celebration

Apr 29, 2025 -

Actor Jeff Goldblum Launches Music Career With New Album

Apr 29, 2025

Actor Jeff Goldblum Launches Music Career With New Album

Apr 29, 2025

Latest Posts

-

Dans Quoi Investir Facilement Solutions Simples Et Accessibles

May 12, 2025

Dans Quoi Investir Facilement Solutions Simples Et Accessibles

May 12, 2025 -

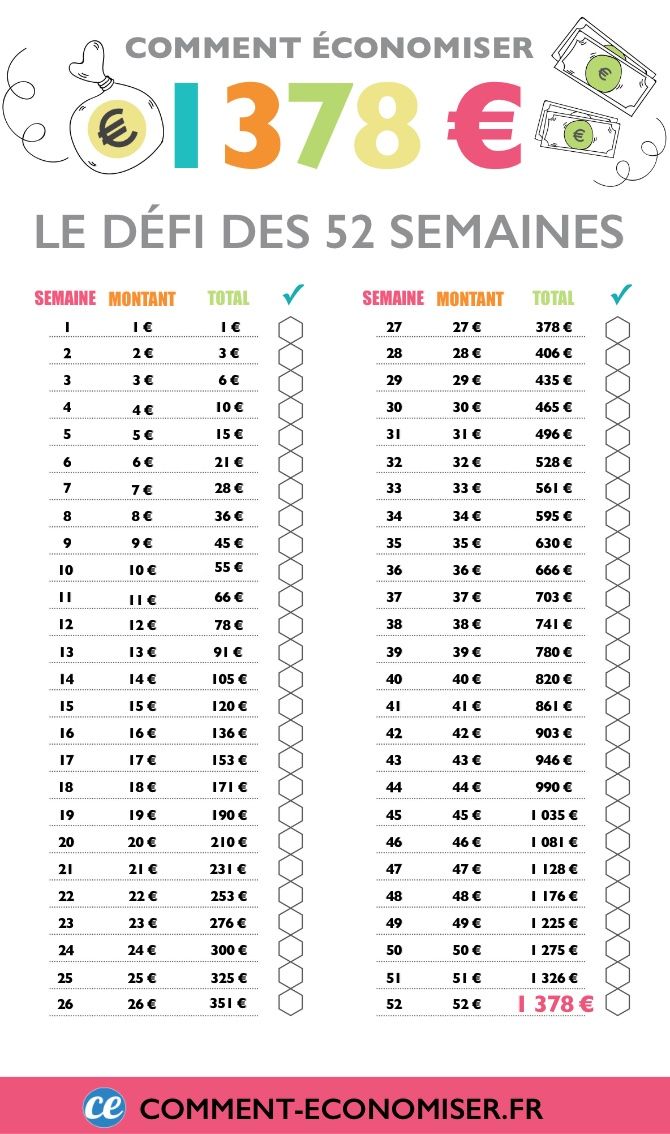

Economiser Intelligemment Conseils Pour Un Budget Equilibre

May 12, 2025

Economiser Intelligemment Conseils Pour Un Budget Equilibre

May 12, 2025 -

Mes Investissements Comment Diversifier Et Optimiser Son Portefeuille

May 12, 2025

Mes Investissements Comment Diversifier Et Optimiser Son Portefeuille

May 12, 2025 -

Reussir Son Budget Guide Complet Pour Economiser Efficacement

May 12, 2025

Reussir Son Budget Guide Complet Pour Economiser Efficacement

May 12, 2025 -

Ou Investir Guide Pratique Pour Choisir Les Bons Placements

May 12, 2025

Ou Investir Guide Pratique Pour Choisir Les Bons Placements

May 12, 2025