The Reality Of Reshoring Manufacturing Jobs To America

Table of Contents

Economic Factors Driving Reshoring and Onshoring

Several powerful economic forces are propelling the reshoring and onshoring movements. The cost advantages of overseas manufacturing, once a dominant factor, are eroding. This is largely due to several key factors:

- Increased labor costs in developing countries: Wage increases in countries like China and Vietnam are narrowing the cost gap with American labor, particularly when automation is considered.

- Rising transportation and logistics expenses: Fuel costs, global shipping congestion, and increasing complexity in international logistics add substantial costs to imported goods. These hidden costs make domestic production increasingly competitive.

- Impact of tariffs and trade policies on import costs: Trade wars and fluctuating tariffs have significantly increased the cost of imported goods, making domestic manufacturing more attractive. Companies are actively seeking ways to mitigate risks associated with global trade uncertainties.

- The role of automation in reducing labor costs in the US: Advanced automation technologies, including robotics and AI, are dramatically reducing labor costs in American manufacturing. This technology allows US manufacturers to compete more effectively on price with overseas producers.

- The benefits of a more resilient and diversified supply chain: The COVID-19 pandemic exposed the vulnerabilities of overly reliant global supply chains. Reshoring and nearshoring offer businesses increased supply chain resilience and reduced reliance on potentially unstable international markets.

Challenges and Obstacles to Reshoring Manufacturing

Despite the compelling economic arguments for reshoring, numerous significant challenges stand in the way. Companies considering bringing manufacturing back to the US must grapple with:

- The skills gap in the American manufacturing workforce: A shortage of skilled labor remains a major hurdle. Finding and training workers with the necessary expertise is crucial for successful reshoring initiatives.

- The need for investment in upgrading infrastructure (roads, ports, energy): Outdated infrastructure in many parts of the US presents a challenge. Investments in modernizing transportation networks, ports, and energy grids are essential to support increased manufacturing activity.

- Navigating complex environmental regulations and compliance: Stringent environmental regulations in the US can represent a higher cost of operation compared to countries with less rigorous standards. Companies must factor in these compliance costs when assessing reshoring feasibility.

- High initial investment costs associated with setting up domestic manufacturing: The capital expenditure required to establish new manufacturing facilities or upgrade existing ones can be substantial, requiring significant upfront investment.

- Competition from established domestic and international players: Existing domestic manufacturers and established international players already operating in the US represent a competitive landscape that new entrants must navigate.

Government Initiatives and Support for Reshoring

Recognizing the importance of reshoring for economic growth and national security, the US government has implemented various programs to incentivize companies to bring manufacturing jobs back home. These initiatives include:

- Tax incentives and credits for companies that reshore: Tax breaks and credits reduce the financial burden of reshoring, making it a more attractive proposition for businesses.

- Government grants for infrastructure improvements and workforce training: Grants help fund crucial infrastructure upgrades and workforce development programs, addressing two major obstacles to reshoring.

- Programs supporting the development of skilled manufacturing labor: Government-funded training programs aim to bridge the skills gap by providing workers with the necessary skills for modern manufacturing jobs.

- Examples of successful government reshoring initiatives: Several successful initiatives demonstrate the positive impact of government support on reshoring efforts, offering valuable case studies for future programs.

Case Studies: Successful Reshoring Stories

Numerous companies have successfully reshored manufacturing operations, demonstrating the viability and benefits of this strategy. These case studies highlight the positive impact on job creation, economic growth, and supply chain resilience. [Insert examples of successful reshoring stories here, linking to relevant articles or company websites.]

The Future of Reshoring Manufacturing in America

The future of reshoring in America is bright, driven by several key factors:

- The role of advanced manufacturing technologies (e.g., AI, robotics): Technological advancements continue to improve efficiency and productivity, further enhancing the competitiveness of American manufacturing.

- The importance of sustainable and environmentally friendly manufacturing practices: Growing demand for sustainable manufacturing creates opportunities for American companies to leverage their commitment to environmental responsibility.

- The impact of geopolitical factors on reshoring decisions: Geopolitical instability and concerns over supply chain security continue to fuel the momentum behind reshoring initiatives.

- Predictions for the growth of American manufacturing in the coming years: Experts predict significant growth in American manufacturing in the coming years, driven by reshoring and onshoring trends.

Conclusion

The decision to reshore manufacturing jobs to America is a complex undertaking, influenced by a variety of economic, logistical, and political factors. While challenges exist, the potential benefits – from increased job creation and economic growth to greater supply chain resilience – are substantial. Government initiatives are playing a key role in facilitating this transition, providing incentives and support for companies committed to bringing manufacturing back home. The future of American manufacturing looks promising, with technology and a renewed focus on domestic production paving the way for a resurgence in this vital sector. Explore the possibilities of reshoring manufacturing jobs to America and unlock the potential for economic growth and job creation. Visit [link to relevant government website] and [link to industry association website] to learn more about reshoring opportunities and available support programs.

Featured Posts

-

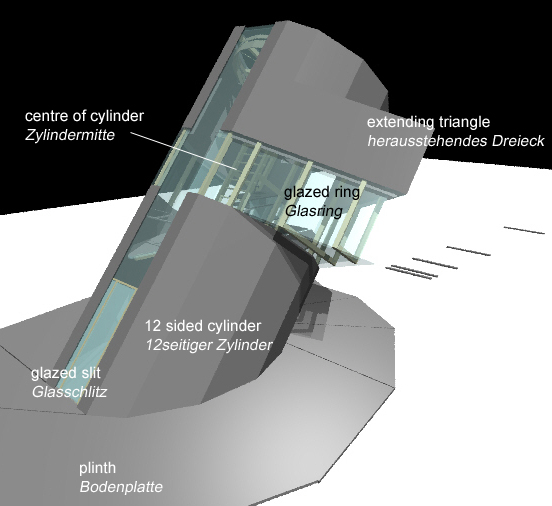

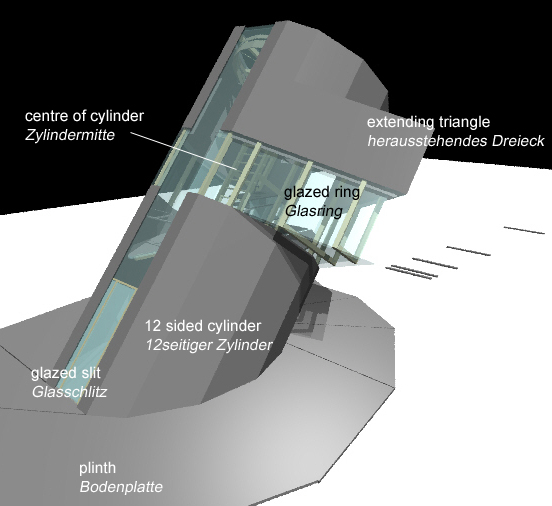

Endgueltige Formgebung Durch Architektin Vor Ort Bestimmt

May 21, 2025

Endgueltige Formgebung Durch Architektin Vor Ort Bestimmt

May 21, 2025 -

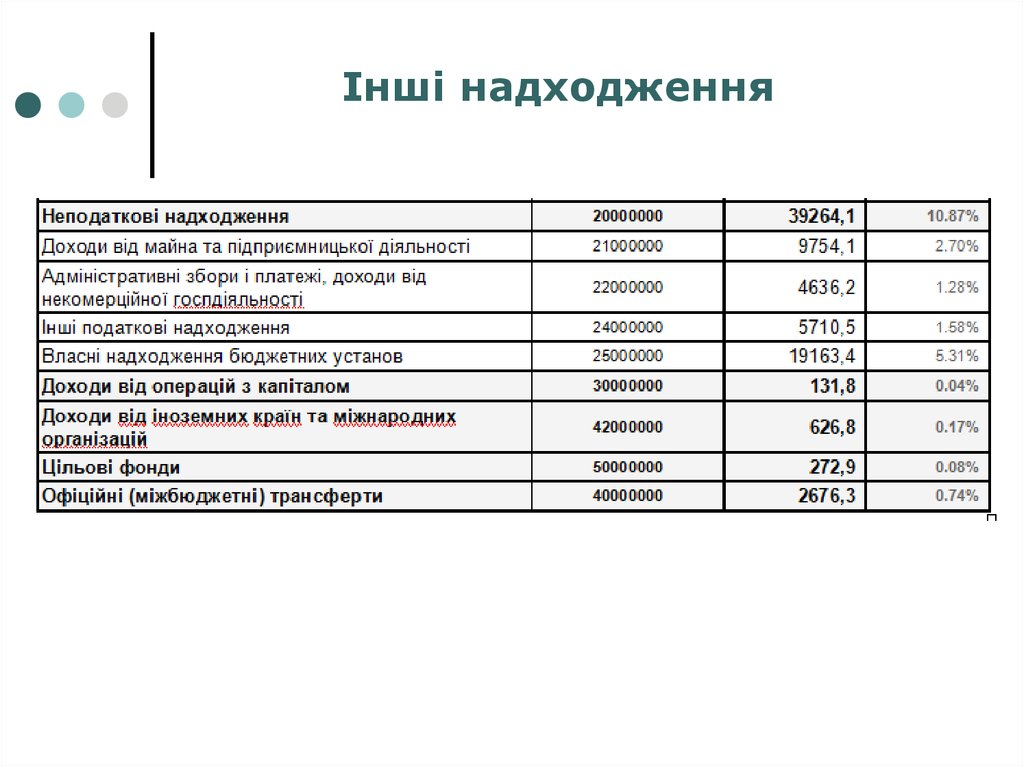

Naybilshi Finansovi Kompaniyi Ukrayini Analiz Dokhodiv Za 2024 Rik

May 21, 2025

Naybilshi Finansovi Kompaniyi Ukrayini Analiz Dokhodiv Za 2024 Rik

May 21, 2025 -

Job Cuts Threaten Popular Abc News Shows Continued Run

May 21, 2025

Job Cuts Threaten Popular Abc News Shows Continued Run

May 21, 2025 -

Understanding The D Wave Quantum Qbts Stock Crash On Monday

May 21, 2025

Understanding The D Wave Quantum Qbts Stock Crash On Monday

May 21, 2025 -

Four Star Admiral Burke Found Guilty Bribery Charges

May 21, 2025

Four Star Admiral Burke Found Guilty Bribery Charges

May 21, 2025

Latest Posts

-

Rtl Group Achieving Streaming Profitability Analysis And Outlook

May 21, 2025

Rtl Group Achieving Streaming Profitability Analysis And Outlook

May 21, 2025 -

Is Mainzs Henriksen The Next Big Managerial Talent After Klopp And Tuchel

May 21, 2025

Is Mainzs Henriksen The Next Big Managerial Talent After Klopp And Tuchel

May 21, 2025 -

Kaellmanin Ja Hoskosen Sopimus Puolan Seuran Kanssa Paeaettyy

May 21, 2025

Kaellmanin Ja Hoskosen Sopimus Puolan Seuran Kanssa Paeaettyy

May 21, 2025 -

Endgueltige Formgebung Durch Architektin Vor Ort Bestimmt

May 21, 2025

Endgueltige Formgebung Durch Architektin Vor Ort Bestimmt

May 21, 2025 -

Henriksen Mainzs Hope To Continue Klopp And Tuchels Legacy

May 21, 2025

Henriksen Mainzs Hope To Continue Klopp And Tuchels Legacy

May 21, 2025