US Army's Right-to-Repair Policy: Enhancing Equipment Readiness And Reducing Costs

Table of Contents

Improving Equipment Readiness Through Enhanced Repair Capabilities

A right-to-repair policy directly addresses the critical issue of equipment downtime. By granting access to repair information and parts, the Army can significantly reduce the time it takes to get vital equipment back online.

Reducing Downtime and Increasing Operational Availability

A right-to-repair policy allows for faster repairs, minimizing downtime of critical equipment. This translates to improved mission readiness and operational availability.

- Faster troubleshooting: Access to repair manuals and diagnostic tools speeds up the identification and resolution of equipment malfunctions.

- Quicker access to parts: Reduced reliance on single vendors and the ability to source parts from multiple suppliers ensures faster repair turnaround times.

- Reduced reliance on single vendors: Competition among parts suppliers helps to ensure timely delivery and competitive pricing.

The impact on operational efficiency is substantial. Minimizing equipment downtime directly contributes to increased operational availability and improved overall mission readiness.

Expanding Repair Options Beyond Original Equipment Manufacturers (OEMs)

A right-to-repair policy opens the door to competition among repair providers. This fosters innovation and drives down costs.

- Increased choice of repair providers: The Army gains access to a wider range of repair services, potentially finding specialized expertise for niche equipment.

- Potential for specialized repair services: Independent repair shops can offer specialized skills and services that may not be readily available from OEMs.

- Fostering innovation in repair techniques: Competition encourages repair providers to develop more efficient and cost-effective repair methods.

The inclusion of independent repair shops supplements OEM services, creating a more robust and resilient repair ecosystem. This leads to competitive pricing and drives repair innovation.

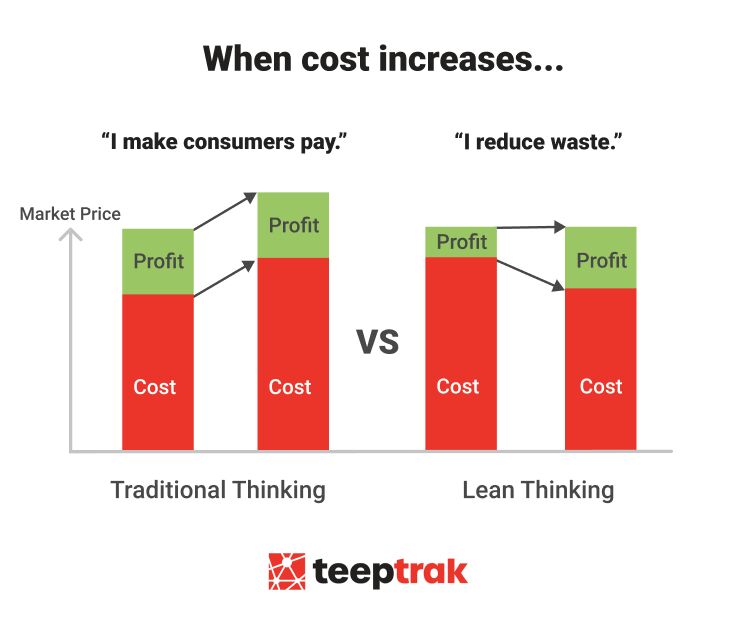

Significant Cost Reduction through a US Army Right-to-Repair Policy

The financial benefits of a right-to-repair policy are significant. By increasing competition and access to parts, the Army can drastically reduce its repair expenses.

Lower Repair Costs

Competition and increased access to parts directly translate to lower repair bills.

- Reduced reliance on expensive OEM parts: The ability to source parts from multiple suppliers drives down the cost of components.

- Lower labor costs from increased competition: A larger pool of repair providers creates a more competitive labor market, reducing overall labor costs.

- Negotiating power for the army: Increased competition empowers the Army to negotiate better prices on parts and services.

This translates to considerable cost reduction, significantly impacting the overall lifecycle cost of military equipment. A detailed repair cost analysis would reveal substantial procurement savings.

Reduced Disposal and Replacement Costs

Extending the lifespan of equipment through effective repair reduces the need for costly replacements.

- Sustainable practices: Repairing equipment reduces waste and minimizes the environmental impact of disposing of old equipment.

- Reduced environmental impact: Fewer replacements mean less manufacturing and transportation, reducing the Army's carbon footprint.

- Lower procurement budgets: By extending the lifespan of existing equipment, the Army can reduce its reliance on expensive new procurements.

This contributes to improved equipment lifecycle management and more sustainable maintenance, resulting in significant waste reduction and a minimized environmental impact.

Challenges and Considerations for Implementing a US Army Right-to-Repair Policy

While the benefits are clear, implementing a right-to-repair policy requires careful consideration of potential challenges.

Intellectual Property Concerns

Protecting sensitive technological information is paramount.

- Data security: Measures must be in place to protect proprietary data from unauthorized access.

- Licensing agreements: Clear licensing agreements are needed to manage the use of intellectual property.

- Maintaining proprietary technology: Strategies need to be developed to balance the benefits of repair access with the need to safeguard sensitive technology.

Ensuring Quality and Safety Standards

Maintaining the safety and reliability of repaired equipment is crucial.

- Certification programs: Establishing certification programs for repair providers ensures consistent quality.

- Standardized repair procedures: Standardizing repair processes helps guarantee safety and reliability.

- Quality assurance protocols: Robust quality control mechanisms are needed to monitor the quality of repairs.

Logistics and Supply Chain Management

Managing a decentralized repair network presents logistical complexities.

- Inventory management: Efficient inventory management is essential to ensure timely access to parts.

- Part sourcing: Reliable and efficient part sourcing strategies are necessary to support the repair network.

- Efficient distribution networks: A well-designed distribution network is crucial for delivering parts to repair facilities.

Securing the Future of US Army Readiness with a Comprehensive Right-to-Repair Approach

Implementing a US Army right-to-repair policy offers significant advantages: improved equipment readiness, substantial cost savings, and enhanced operational efficiency. Addressing the challenges through careful planning and implementation is crucial. Learn more about the ongoing discussions and initiatives related to the US Army's right-to-repair policy and advocate for its implementation to improve military readiness and cost-effectiveness. A strong right-to-repair initiative is vital for a more efficient and cost-effective army maintenance policy and improved military equipment repair.

Featured Posts

-

2025s Best Online Casino In Ontario Mirax Casino Review And Guide

May 18, 2025

2025s Best Online Casino In Ontario Mirax Casino Review And Guide

May 18, 2025 -

Kanye Vest Ta B Yantsa Tsenzori Podrobitsi Rozstavannya

May 18, 2025

Kanye Vest Ta B Yantsa Tsenzori Podrobitsi Rozstavannya

May 18, 2025 -

Worldwide Reddit Outage Users Report Service Disruptions

May 18, 2025

Worldwide Reddit Outage Users Report Service Disruptions

May 18, 2025 -

Amanda Bynes Seen With Friend After Only Fans Announcement

May 18, 2025

Amanda Bynes Seen With Friend After Only Fans Announcement

May 18, 2025 -

I Tzenifer Aniston Vgike Me Ton Pentro Paskal Oi Fimes Kai Oi Antidraseis

May 18, 2025

I Tzenifer Aniston Vgike Me Ton Pentro Paskal Oi Fimes Kai Oi Antidraseis

May 18, 2025