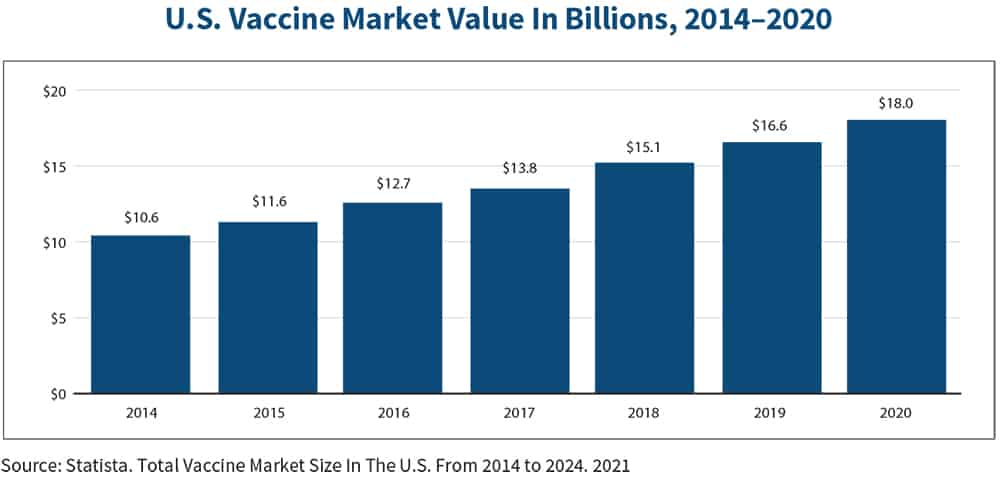

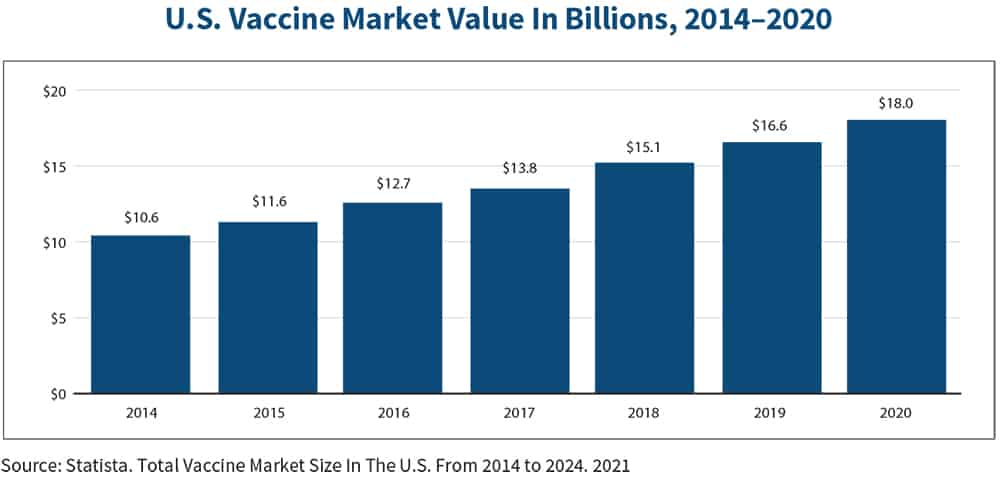

Analyzing The Booming Vaccine Packaging Market

Table of Contents

H2: Growth Drivers of the Vaccine Packaging Market

The burgeoning demand for vaccine packaging is fueled by several key factors. Understanding these drivers is crucial for both established players and new entrants seeking a foothold in this dynamic market.

H3: Increasing Global Vaccination Rates

The global push for increased vaccination coverage is a primary catalyst for market expansion. The rise in infectious diseases, coupled with successful vaccination campaigns against various illnesses, has significantly boosted the demand for effective and reliable vaccine packaging.

- Increased incidence of infectious diseases: Outbreaks of diseases like influenza, measles, and COVID-19 highlight the critical need for widespread vaccination and, consequently, robust packaging solutions.

- Government initiatives promoting vaccination: Many governments worldwide are implementing national immunization programs and incentivizing vaccination, fueling the demand for vaccine packaging solutions.

- Expanding immunization programs in developing countries: The expansion of vaccination programs in developing nations presents a significant growth opportunity for the vaccine packaging market, particularly for cost-effective and temperature-stable packaging options.

The World Health Organization (WHO) projects a continued increase in global vaccination coverage, further solidifying the market's growth trajectory. This projected growth underscores the significant demand for innovative and reliable vaccine packaging solutions in the coming years.

H3: Stringent Regulatory Requirements and Quality Control

The pharmaceutical industry is heavily regulated, and vaccine packaging is no exception. Compliance with stringent quality control standards and regulatory requirements significantly impacts the market.

- Compliance with GMP (Good Manufacturing Practices): Manufacturers must adhere to strict GMP guidelines to ensure the safety and efficacy of vaccines. This necessitates investing in high-quality materials and manufacturing processes.

- FDA regulations and ISO standards: Meeting FDA regulations in the US and ISO standards internationally is mandatory, increasing the cost of production and entry barriers for new players.

- Traceability requirements: Robust traceability systems are essential to ensure product accountability and prevent counterfeiting. This adds complexity and cost to the vaccine packaging process.

Meeting these regulatory hurdles necessitates significant investment in quality control, impacting the overall cost of vaccine packaging. However, stringent regulations also ensure product safety and consumer trust, solidifying market stability.

H3: Advancements in Vaccine Packaging Technology

Innovation is a key driver of the vaccine packaging market. Advancements in materials science and packaging design are improving vaccine stability, efficacy, and ease of handling.

- Use of advanced polymers: New polymers offer improved barrier properties, preventing moisture and oxygen ingress, thereby enhancing vaccine shelf life.

- Biodegradable materials: The increasing emphasis on sustainability is driving the adoption of biodegradable and recyclable packaging materials, minimizing the environmental impact.

- Improved temperature control systems: Sophisticated cold chain packaging solutions, such as temperature-indicating labels and insulated containers, ensure vaccine integrity during transportation and storage.

- Smart packaging with temperature sensors: Smart packaging incorporates sensors that monitor temperature and humidity, providing real-time data on vaccine condition.

These technological advancements significantly enhance vaccine stability and delivery, contributing to improved public health outcomes and driving market growth.

H2: Key Players and Market Segmentation

The vaccine packaging market is characterized by a diverse range of players and a complex segmentation based on packaging type and geography.

H3: Major Players in the Vaccine Packaging Market

Several major players dominate the market, leveraging their expertise in materials science, manufacturing, and logistics.

- Schott: A leading provider of pharmaceutical packaging solutions, Schott offers a wide range of vials and cartridges for vaccines.

- West Pharmaceutical Services: A global leader in drug delivery systems, West offers a comprehensive portfolio of stoppers and closures for vaccine vials.

- Corning: Known for its expertise in glass technology, Corning provides high-quality glass vials and other packaging components for vaccines.

These companies and others are constantly innovating and expanding their product lines to meet the growing demands of the market.

H3: Market Segmentation by Packaging Type

The market is segmented based on different packaging types, each with its advantages and disadvantages.

- Vials: Traditional glass vials remain the most prevalent packaging type for vaccines, offering good stability and compatibility with various formulations.

- Syringes: Pre-filled syringes offer convenience and reduce the risk of contamination, driving their increasing adoption.

- Prefilled syringes: These offer enhanced convenience and improved safety profiles.

Market share varies across packaging types, driven by factors such as cost, convenience, and regulatory requirements.

H3: Market Segmentation by Geography

The vaccine packaging market exhibits significant regional variations in growth rates, driven by factors like healthcare infrastructure and vaccination policies.

- North America and Europe: These regions represent mature markets with established healthcare infrastructure, driving steady growth.

- Asia-Pacific: This region is witnessing rapid growth, driven by increasing vaccination rates and expanding healthcare infrastructure.

Understanding regional variations is crucial for effective market penetration and strategic planning.

H2: Challenges and Future Trends in Vaccine Packaging

Despite significant growth, the vaccine packaging market faces various challenges, alongside exciting future trends.

H3: Challenges in Maintaining the Cold Chain

Maintaining the cold chain throughout the vaccine's lifecycle presents a significant challenge.

- Maintaining consistent cold chain integrity: Ensuring consistent low temperatures during transportation and storage is crucial for vaccine efficacy. Breaks in the cold chain can lead to vaccine spoilage and loss.

- Cost of cold chain logistics: Maintaining a robust cold chain infrastructure is expensive, especially in remote or underserved areas.

- Technological advancements to improve cold chain management: Innovations like passive and active temperature-controlled packaging and real-time monitoring systems are addressing these challenges.

Overcoming these cold chain challenges is essential for ensuring vaccine efficacy and accessibility worldwide.

H3: Sustainability Concerns and Environmental Impact

The environmental impact of vaccine packaging is gaining increased attention.

- Use of biodegradable materials: The transition to biodegradable and recyclable packaging materials is crucial for reducing the environmental footprint of the industry.

- Reduction of packaging waste: Minimizing packaging size and optimizing supply chains can help reduce waste generation.

- Eco-friendly manufacturing processes: Adopting sustainable manufacturing practices can further lessen the environmental impact.

Addressing sustainability concerns is vital for the long-term viability and social responsibility of the vaccine packaging market.

H3: Future Technological Advancements

The future of vaccine packaging is marked by significant technological advancements.

- Smart packaging: Smart packaging incorporating sensors and data logging capabilities offers real-time monitoring of vaccine condition and enhances traceability.

- Personalized packaging: Tailored packaging solutions may emerge, accommodating specific vaccine formulations and delivery requirements.

- Improved vaccine delivery systems: Innovations in vaccine delivery, such as microneedle patches, will necessitate new packaging solutions.

These advancements will enhance vaccine stability, safety, and delivery, transforming the vaccine packaging landscape.

3. Conclusion

The vaccine packaging market is poised for continued growth, driven by increasing global vaccination rates, stringent regulations, and technological advancements. While challenges remain in maintaining the cold chain and addressing sustainability concerns, the industry is actively innovating to overcome these hurdles. The adoption of smart packaging, biodegradable materials, and improved cold chain solutions are shaping the future of this crucial sector. Stay informed on the evolving vaccine packaging market; discover innovative solutions in vaccine packaging and explore the latest advancements in vaccine packaging technology to contribute to global health initiatives.

Featured Posts

-

Analyzing Polands Election Runoff The Impact On The European Right

May 30, 2025

Analyzing Polands Election Runoff The Impact On The European Right

May 30, 2025 -

Jacob Alons Fairy In A Bottle Todays Top Tune

May 30, 2025

Jacob Alons Fairy In A Bottle Todays Top Tune

May 30, 2025 -

Kawasaki Disease A Novel Respiratory Virus As The Culprit

May 30, 2025

Kawasaki Disease A Novel Respiratory Virus As The Culprit

May 30, 2025 -

The La Wildfires And The Disturbing Trend Of Disaster Betting

May 30, 2025

The La Wildfires And The Disturbing Trend Of Disaster Betting

May 30, 2025 -

Sudden Departure Deutsche Banks Distressed Sales Head Moves To Morgan Stanley

May 30, 2025

Sudden Departure Deutsche Banks Distressed Sales Head Moves To Morgan Stanley

May 30, 2025